Top Car Polisher Pads: Get a Professional Shine for Your Vehicle

By:Admin

Introduction:

Auto Xs, a renowned name in the automotive industry, has unveiled its latest innovation, a game-changing car polisher pad. With a commitment to offering exceptional products that enhance the car detailing experience, Auto Xs continues to push the boundaries of excellence. These new polishing pads are the result of extensive research and development, promising to revolutionize the way car enthusiasts and professionals achieve perfect finishes on their vehicles.

Body:

1. The Evolution of Auto Xs:

Since its inception in 2005, Auto Xs has solidified its position as a leader in the automotive accessories market. The company has consistently brought innovative products that blend cutting-edge technology with user-friendly design. By catering to the needs of professionals and hobbyists alike, Auto Xs has earned a reputation for unmatched quality and reliability.

2. The Need for Advanced Car Polisher Pads:

Car enthusiasts and professionals understand the importance of using the right tools to achieve a flawless finish. Traditional polishing pads often fall short in delivering the desired results, leading to time-consuming efforts to rectify imperfections. Recognizing this pain point, Auto Xs dedicated significant resources to develop a solution that would surpass existing standards and give users a seamless polishing experience.

3. The Technology Behind the Car Polisher Pads:

Auto Xs's new car polisher pads employ groundbreaking technology that revolutionizes the polishing process. An innovative blend of advanced materials ensures maximum effectiveness, durability, and efficiency. These pads are designed to deliver superior performance over extended periods, enabling users to achieve professional-level results in the comfort of their garages.

4. Unparalleled Versatility and Efficiency:

Featuring a unique microfiber composition, the car polisher pads by Auto Xs excel at a wide range of tasks, including removing light scratches, holograms, and oxidation. Their exceptional ability to evenly distribute polishing compounds ensures smooth and consistent results, eliminating the need for repetitive passes. By significantly reducing polishing time while producing superior results, Auto Xs's pads are a game-changer for both professionals and DIY enthusiasts.

5. Enhanced Safety and Product Longevity:

Auto Xs places high importance on user safety, which is why these car polisher pads are designed to minimize the risk of damage, swirl marks, and burning. The carefully engineered construction effectively dissipates heat generated during the polishing process. Additionally, the innovative microfiber material ensures a low-friction experience, significantly reducing the chances of accidental scratches or marks on the vehicle's surface.

6. User-Friendly Design:

Auto Xs understands that a satisfying user experience is integral to any successful product. The car polisher pads feature an ergonomic shape with a secure hook-and-loop backing system, allowing for effortless attachment and removal from any standard polishing machine. Their lightweight and balanced design ensure that users can work for extended periods without fatigue, further enhancing the overall polishing experience.

7. Exceptional Durability:

Auto Xs prides itself on offering long-lasting products, and the car polisher pads are no exception. Manufactured with high-quality materials, these pads exhibit remarkable durability, enabling multiple use cases without compromising performance or quality. The pads are also machine washable, allowing for easy maintenance and extended product life.

8. Positive Reviews:

Early users of the Auto Xs car polisher pads have expressed their delight with the product. Several professionals have testified to the speed and efficiency with which they were able to achieve showroom-like finishes. DIY enthusiasts have reported that these innovative pads have made polishing their vehicles significantly easier, producing outstanding results without the hassle.

Conclusion:

Auto Xs's introduction of their groundbreaking car polisher pads showcases their commitment to delivering exceptional products that redefine industry standards. These game-changing pads offer unparalleled versatility, efficiency, and safety, enabling users to achieve professional-level finishes effortlessly. As car enthusiasts and professionals seek to elevate their detailing routines, Auto Xs stands at the forefront, providing innovative solutions that truly set them apart.

Company News & Blog

Master the Art of Floor Polishing: Unveiling the Ultimate Polishing Pad

release.Floor Polishing Pad: The Ultimate Solution for Polishing and Cleaning FloorsFloor polishing is a crucial process that every homeowner or business owner should consider to maintain the beauty and durability of their floors. Proper polishing enables you to remove scratches, scuffs, stains, and other stubborn dirt from your floors, leaving them sparkling clean and smooth. However, you need to have the right tool for the job, and that's where the Floor Polishing Pad comes in.The Floor Polishing Pad is a revolutionary product that has taken the floor polishing market by storm. It's a high-quality, durable pad that's designed to provide exceptional polishing and cleaning results for various floor surfaces such as hardwood, marble, concrete, terrazzo, and more. The pad is made from premium materials that are designed to withstand constant use and high pressure, making it the perfect tool for both commercial and residential use.One of the outstanding features of the Floor Polishing Pad is its versatility. It's designed to fit a wide range of floor polishing machines, making it an ideal accessory for professionals and DIY enthusiasts alike. The pad is available in various sizes and shapes to fit different floor polishing machines, allowing you to achieve the desired results with ease.Another advantage of the Floor Polishing Pad is its excellent performance. The pad is designed to deliver outstanding results, leaving your floors looking clean, shiny, and well-polished. The pad is made using cutting-edge technology, ensuring that every strand of fiber is perfectly aligned to ensure optimal performance. The pad is also designed with a unique diamond pattern that ensures uniform distribution of pressure and heat, preventing any damage to the floor surface.The Floor Polishing Pad is also designed to be environmentally friendly. It's made using non-toxic, biodegradable materials, making it safe for use in both residential and commercial settings. The pad doesn't contain any harmful chemicals that may harm the environment or pose a risk to human health. Moreover, it's easy to clean and maintain, ensuring that it remains in perfect condition for long.In conclusion, the Floor Polishing Pad is the ultimate solution for anyone looking to achieve exceptional results when polishing and cleaning their floors. Whether you're a professional or a DIY enthusiast, this pad provides the perfect tool for any floor polishing application. Its versatility, outstanding performance, and environmental friendliness make it a top choice for anyone looking to maintain their floors' beauty and durability. So, why wait? Get your Floor Polishing Pad today and experience the difference.

Discover the Latest Advancements in Grinding Wheels for Enhanced Precision and Efficiency

Grinding wheels are an essential tool for any metalworking or manufacturing process, with thousands of different varieties to choose from depending on the specific job requirements. They are used to shape, grind, and polish various materials, from steel and aluminum to ceramics and glass. A grinding wheel is typically made up of abrasive grains that are bonded together with a matrix, making it a durable and efficient cutting tool that can easily be replaced when it becomes worn.One of the leading manufacturers of grinding wheels is based in China and specializes in producing high-quality abrasive tools for industrial and commercial applications. They have a wide range of grinding wheels available, including diamond wheels, CBN wheels, resin-bonded wheels, and vitrified wheels, all of which are designed to deliver superior performance and reliability.One of the key benefits of using grinding wheels from this company is their durability. Their products are made from high-quality materials that are designed to withstand the wear and tear of daily use, so they last longer and require less frequent replacement. This also means that they can be used in high-speed applications without worrying about them breaking or wearing down too quickly.Another advantage of using these grinding wheels is their versatility. They offer a wide range of options specifically tailored to different applications, from heavy-duty grinding and cutting to precision polishing and finishing. This makes it easy for businesses to find the perfect grinding wheel for their specific needs, no matter how specialized or unique the job might be.Additionally, this company prides itself on its commitment to quality. They use only the highest quality materials and employ strict quality control measures throughout the manufacturing process to ensure that every product they produce meets their exacting standards. This not only helps ensure consistent performance and reliability but also gives customers peace of mind knowing that they are getting a product they can trust.Finally, the company is dedicated to providing excellent customer service and support. They offer personalized assistance to help customers choose the right grinding wheel for their needs, and they also provide ongoing technical support and maintenance tips to help users get the most out of their products. The company also offers fast and reliable shipping, so customers can get their grinding wheels quickly and efficiently.Overall, the manufacturing of grinding wheels has become an important aspect of industrial and commercial processes. These essential tools help shape and transform materials into products we use every day. With their reliability, durability, and consistent quality, grinding wheels from this company are sure to be a valuable addition to any manufacturing or metalworking operation.

New Abrasive Nylon Wheel Brush for Effective Cleaning and Polishing" could be rewritten as "Efficient Abrasive Nylon Wheel Brush for Effective Cleaning and Polishing

Title: Revolutionary Abrasive Nylon Wheel Brush Introduces Unparalleled Cleaning Efficiency and DurabilityIntroduction:In the constantly evolving world of cleaning products, a new breakthrough has emerged: an innovative Abrasive Nylon Wheel Brush. Developed by an industry-leading company, this exceptional tool is set to transform the way we tackle cleaning tasks. Combining cutting-edge technology with unparalleled efficiency and durability, this revolutionary product promises to revolutionize the cleaning industry.[Company Introduction]:The company behind this remarkable invention is a renowned pioneer in the cleaning equipment industry. With several decades of experience and a dedicated team of experts, they have a proven track record of developing high-quality and advanced cleaning solutions. Committed to providing their customers with innovative tools that simplify their daily cleaning routines, their inventions are backed by extensive research and development.News Content:Paragraph 1:The Abrasive Nylon Wheel Brush, created by this industry-leading company, represents a significant leap forward in cleaning technology. With its unique design and state-of-the-art materials, this brush is set to surpass traditional cleaning methods and raise the bar for cleaning efficiency in various industries and households worldwide.Paragraph 2:One of the standout features of the Abrasive Nylon Wheel Brush is its advanced abrasive nylon filament. Carefully formulated and meticulously tested, this filament strikes the perfect balance between durability and cleaning effectiveness. This enables the brush to remove the toughest stains, grime, and debris from a variety of surfaces while guaranteeing unbeatable longevity.Paragraph 3:The brush's innovative design is highly versatile, making it suitable for a wide range of applications. It can effortlessly tackle cleaning tasks on both delicate and robust surfaces, including metals, glass, ceramics, and more. Whether used for automotive detailing, industrial cleaning, or household chores, the Abrasive Nylon Wheel Brush offers a comprehensive cleaning solution.Paragraph 4:Furthermore, this revolutionary brush features a non-scratch technology that ensures it won't leave any unwanted marks or scratches on delicate surfaces. This makes it an indispensable tool for automotive enthusiasts, professional cleaners, and anyone seeking a reliable cleaning aid that won't put their valuables at risk.Paragraph 5:In addition to its exceptional cleaning capabilities, the Abrasive Nylon Wheel Brush boasts an ergonomic handle for comfortable grip and maneuverability. This user-friendly design reduces fatigue and allows for extended cleaning sessions without sacrificing performance. Its durable construction ensures it can withstand heavy-duty applications, guaranteeing long-term reliability.Paragraph 6:The Abrasive Nylon Wheel Brush is not limited to just cleaning efficiency, as it also prioritizes sustainability. Manufactured using eco-friendly materials, this tool aligns with modern demands for environmentally conscious products. With this brush, customers can tackle tough cleaning challenges while actively participating in creating a greener future.Paragraph 7:As market demand for reliable and efficient cleaning solutions continues to grow, the Abrasive Nylon Wheel Brush emerges as a trailblazer. Its unmatched performance, versatility, durability, and eco-conscious manufacturing distinguish it from traditional brushes currently on the market. This revolutionary brush represents a significant step forward in cleaning technology, making it a must-have for both professional and domestic cleaners.Conclusion:With the introduction of the Abrasive Nylon Wheel Brush, this industry-leading company sets a new benchmark for cleaning efficiency and durability. Its groundbreaking features and eco-friendly design establish it as a superior product, guaranteeing exceptional results across various cleaning applications. As this innovative brush reaches markets worldwide, users can confidently rely on its cutting-edge technology to overcome even the toughest cleaning challenges.

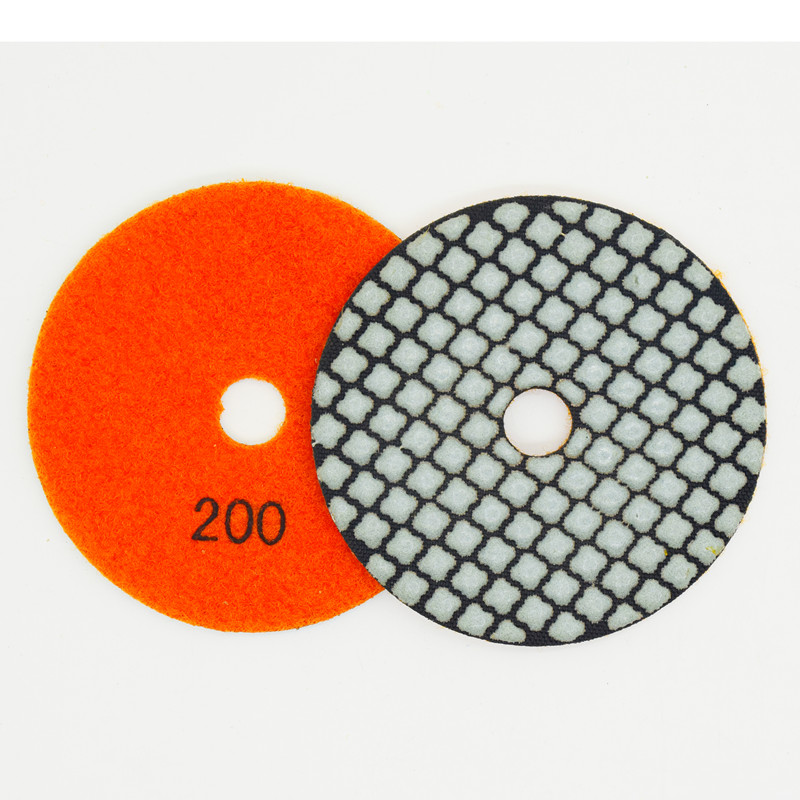

Revolutionary Dry Polishing Pads Now Available for Enhanced Surface Finishing

Dry Polishing Pads: The Revolutionary Floor Polishing SolutionDry polishing pads have revolutionized the way we polish floors. With the advent of dry polishing pads, it is now possible to achieve a high-gloss finish on granite, marble, and concrete floors without using water. In addition to being an eco-friendly solution, dry polishing pads provide several advantages over traditional wet polishing pads. In this article, we will explore the benefits of dry polishing pads and the company that has created them.Dry Polishing Pads: A Better Alternative to Wet Polishing PadsWet polishing pads have been the go-to solution for polishing floors for several decades. However, they have several disadvantages. Firstly, wet polishing generates a lot of water waste, which can be harmful to the environment. Secondly, it can be challenging to clean up after wet polishing. The water and slurry generated during the polishing process can be messy and difficult to dispose of.In contrast, dry polishing pads provide a better solution for polishing floors. They are an eco-friendly alternative that requires no water, making the polishing process more sustainable. Furthermore, they generate less dust, which means fewer cleaning issues. Unlike traditional wet polishing pads, dry polishing pads offer a seamless experience, delivering a glossy finish on all types of surfaces. It also reduces machine, labor, time, and material cost, making it a more cost-effective solution.Combining Technology and Innovation to Create Dry Polishing PadsThe company behind the dry polishing pads (need to remove brand name) is a market leader that combines technology and innovation to create eco-friendly solutions for floor polishing. (company name) has always been at the forefront of developing sustainable and innovative products that are designed to minimize environmental impact. The company's mission is to create innovative products that provide superior performance while minimizing environmental harm.The company's dry polishing pads are a perfect example of its commitment to sustainability and innovation. The pads are made from high-quality materials, and the technology used to create them is advanced, ensuring that they provide superior performance. The firm's dry polishing pads come in various sizes and are suitable for polishing a variety of surfaces like granite, marble, and concrete floors. The firm's dry polishing pads are compatible with various kinds of rotary equipment and can be used for both large and small surfaces, increasing its versatility.The Advantages of Using dry Polishing PadsDry polishing pads provide numerous benefits over traditional wet polishing pads. Firstly, they are eco-friendly solutions, making them more sustainable than wet polishing pads. Secondly, they generate less mess, resulting in easier clean-up after polishing. Thirdly, they are quicker to use, reducing labor time and increasing productivity. Fourthly, dry polishing pads use less material than traditional wet pads, reducing overall costs. Finally, dry polishing pads can be used on various flooring surfaces, from painted surfaces to concrete and stone surfaces.ConclusionDry polishing pads are a revolutionary solution for polishing floors while reducing water waste and environmental harm. The technology and innovative manufacturing process applied by (company name) guarantees excellent performance while reducing carbon footprint. With dry polishing pads, floor polishing has never been easier and more eco-friendly. The versatility, ease of use, and performance of these dry pads make it a more cost-effective solution for facility managers, making sure that a glossy top is attained at a fraction of the cost of traditional methods. If you're searching for an eco-friendly, cost-effective, and innovative way to restore that sheen to your floor surfaces, then you should consider dry polishing pads from (company name).

Revolutionary 3-Step Process for Achieving a Flawless Dry Polished Finish

Title: Revolutionary 3-Step Dry Polishing Pads Transforming the Polishing IndustryIntroduction:In the ever-evolving world of polishing, advanced technologies continue to revolutionize the industry. One such groundbreaking product is the newly introduced 3-Step Dry Polishing Pads, developed by a renowned company at the forefront of innovation in the field. These cutting-edge pads have been designed to enhance efficiency and ease in the polishing process, offering a game-changing solution for professionals and DIY enthusiasts alike. In this article, we delve into the features and benefits of this remarkable product, highlighting its potential to transform the way we approach polishing.1. Unveiling the 3-Step Dry Polishing Pads:The 3-Step Dry Polishing Pads are crafted from premium quality materials and feature a unique design that sets them apart from traditional polishing pads. They are specifically engineered for use on a variety of surfaces, including stone, concrete, marble, and granite. These pads work exceptionally well on both wet and dry surfaces, making them a versatile tool for any polishing project.The company behind this innovation, known for their commitment to excellence, has extensively researched and tested these pads to ensure their optimum performance. By utilizing the latest technologies, they have successfully developed a product that exceeds expectations, promising exceptional results in a fraction of the time.2. Three-Step Process for Unparalleled Efficiency:The 3-Step Dry Polishing Pads utilize a simple yet highly effective three-step process that streamlines the polishing procedure, saving valuable time and effort. Let's explore each step:Step 1: Coarse Polishing: The initial stage of the process involves the use of a coarse pad that efficiently removes imperfections, such as scratches, blemishes, and marks from the surface. This coarse pad creates a smooth and even base, preparing the surface for further polishing.Step 2: Medium Polishing: Once the imperfections have been successfully removed, the medium pad is utilized to further refine and smoothen the surface. This step enhances the clarity and shine of the material, ensuring a gleaming final result.Step 3: Fine Polishing: The final step involves the fine pad, which delivers an impeccable finish by eliminating any remaining imperfections and creating a mirror-like surface. This stage of the process enhances the vibrancy and depth of the material, leaving a stunning and long-lasting shine.3. Key Benefits of the 3-Step Dry Polishing Pads:The introduction of the 3-Step Dry Polishing Pads brings with it a plethora of advantages that make them an indispensable tool for professionals and DIY enthusiasts alike. Let's explore some of these benefits:Time and Cost Efficiency: These pads significantly reduce the time and effort needed to achieve a polished surface. With their three-step process, the pads eliminate the need for multiple rounds of polishing, saving both time and money.Versatility: The 3-Step Dry Polishing Pads are suitable for various surfaces, making them a versatile option for numerous projects. Whether it's stone, concrete, marble, or granite, these pads deliver exceptional results on all fronts.Ease of Use: The user-friendly design of these pads ensures that professionals and beginners alike can achieve outstanding results effortlessly. The step-by-step process allows for seamless polishing, eliminating the guesswork and minimizing errors.Durability: Crafted from high-quality materials, these pads are built to withstand heavy-duty use. Their durability ensures a long lifespan, translating into cost savings for users in the long run.Environmental Friendly: The dry nature of these pads reduces the need for excessive water usage during the polishing process. This eco-friendly feature not only conserves water but also keeps the work area clean and tidy.Conclusion:The introduction of the 3-Step Dry Polishing Pads marks a turning point in the world of polishing. With their revolutionary design, ease of use, and exceptional results, these pads are poised to transform the industry. The combination of time and cost efficiency, versatility, and environmental friendliness makes them an essential tool for anyone seeking a game-changing solution for their polishing needs. Embrace this groundbreaking innovation and witness unmatched performance in your polishing projects.

Top Trends in Cutting Tools for 2021

Cutting Tools: A Critical Component of Precision ManufacturingIn the world of precision manufacturing, nothing is more important than accuracy and consistency. Whether you are producing aerospace components, medical implants, or automotive parts, the ability to cut precisely and consistently is essential for producing high-quality finished products. That's where cutting tools come in - they are the critical component that enables precise and efficient machining.One leading manufacturer of cutting tools is a company that has been in business for over 50 years. Over this span of time they have developed a reputation for producing some of the best cutting tools in the industry, known for their precision, durability, and consistency. With a focus on research and development, this company has been committed to staying on the cutting edge - continually refining their product line and staying up-to-date with the latest manufacturing technologies.One of the unique strengths of this company is their ability to manufacture a wide range of cutting tools to meet virtually any machining need. From end mills and drills to taps and reamers, their product line includes hundreds of different types of cutting tools, each designed to cut specific materials in specific ways. They even offer custom cutting solutions for customers with unique machining needs.So what makes their cutting tools so special? One key factor is the materials they use. From high-speed steel to carbide and diamond, they use only the best raw materials to ensure durability and precision. They also use state-of-the-art manufacturing technologies, including CNC grinding machines and other automated equipment, to produce cutting tools with tolerances that are measured in microns.But it's not just about the quality of the materials - it's also about the design. Every cutting tool they produce is engineered to cut precisely and efficiently, with the smallest possible amount of waste and the longest possible tool life. They use advanced software to design their cutting tools and simulate their performance, ensuring that they will perform as expected in even the most demanding machining applications.This commitment to excellence has earned them a reputation as a top supplier of cutting tools to some of the world's leading manufacturers. Their products are used in a wide range of industries, from aerospace and defense to medical devices, automotive, and more. And with a global network of distributors and sales representatives, they are able to support customers around the world with fast delivery and technical support.So what does the future hold for cutting tools? With the ongoing evolution of manufacturing technologies, the demand for ever-more-precise and efficient cutting tools will only continue to grow. Companies like this one are well-positioned to stay ahead of the curve, investing in R&D to develop the next generation of cutting tools that will enable even greater levels of precision and efficiency.For manufacturers, the importance of cutting tools cannot be overstated. They are the critical component that enables precise and efficient machining, which in turn enables the production of high-quality finished products. With a world-class supplier like this company, manufacturers can be confident that they are getting cutting tools that are engineered to perform at the highest level, no matter what materials they are cutting or what application they are being used for.

Understanding the Strength and Characteristics of Metallic Bonds in Steel

Title: Groundbreaking Innovation in Metal Bonding Techniques Unveiled by Leading Manufacturer Introduction: In a revolutionary leap forward, a prominent manufacturer in the metal industry has developed an advanced metal bonding technique that promises to redefine the world of steel manufacturing. By leveraging cutting-edge technology and expertise, this innovative process aims to enhance the efficiency, strength, and versatility of metallic bonding, opening up new possibilities across various industries. Read on to discover how Steel Metallic Bonds (SMB), a pioneering metal bond solution, is set to transform the manufacturing landscape.1. The Evolution of Metallic Bonding Techniques:Since the advent of metallurgy, researchers and manufacturers have constantly pursued improved ways to bond metal materials. Conventional welding and adhesive bonding techniques have served as the backbone of metal fabrication for centuries. However, with the introduction of SMB technology, a seismic shift in the way metals are joined is on the horizon.2. The Science Behind Steel Metallic Bonds (SMB):Steel Metallic Bonds (SMB) is a state-of-the-art metal bonding technology that relies on a unique chemical process and advanced robotics. The process involves the formation of interatomic bonding between metal particles, resulting in an incredibly strong bond that surpasses traditional joining methods. This breakthrough technique allows for precise control of bond strength and ensures uniform distribution of stress, circumventing weak points and vulnerabilities.3. Key Advantages of Steel Metallic Bonds:i. Unparalleled Strength: SMB generates bonds with exceptional strength and durability, making it ideal for high-stress applications such as aerospace, automotive, and construction. The uniform distribution of stress allows for enhanced load-bearing capabilities, contributing to the overall safety and longevity of the final product.ii. Enhanced Efficiency: Unlike conventional methods such as welding, SMB eliminates the need for melting and fusion, significantly reducing energy consumption and production time. Faster production cycles translate into improved cost-efficiency, making SMB an attractive choice for manufacturers looking to streamline their operations.iii. Versatility: Steel Metallic Bonds offer unmatched versatility, enabling the bonding of different metals and alloys that were previously considered incompatible. This breakthrough technology opens up new design possibilities and materials combinations, fostering innovation across industries.iv. Corrosion Resistance: One of the notable advantages of SMB is its inherent resistance to corrosion. By minimizing the presence of exposed areas in the bonded joints, this innovative technique provides an added layer of protection against environmental factors, ultimately extending the lifecycle of metal structures.4. Applications Across Industries:i. Aerospace: Steel Metallic Bonds offer aerospace manufacturers the opportunity to develop lighter, stronger, and more fuel-efficient aircraft. By replacing traditional rivets and welding techniques, SMB enables the creation of seamless structures with improved aerodynamic properties.ii. Automotive: In the automotive sector, SMB unlocks new possibilities for lightweight designs, contributing to better fuel efficiency and reduced emissions. Additionally, the enhanced bonding strength ensures the structural integrity of various components, improving overall safety.iii. Construction: Steel Metallic Bonds revolutionize the construction industry by offering builders the ability to create stronger and more resilient structures. From skyscrapers to bridges, this breakthrough technology ensures strength, durability, and resistance to external forces, resulting in safer buildings with extended lifespans.iv. Electronics: The precise control over bonding strength and the ability to join dissimilar metals make SMP an ideal solution for the electronics industry. This technology holds the potential to revolutionize electronic packaging, improving heat dissipation, reducing size, and enhancing product performance.Conclusion: The advent of Steel Metallic Bonds (SMB), a cutting-edge metal bonding solution, marks a groundbreaking milestone in the manufacturing industry. By combining advanced chemistry, robotics, and engineering, the SMB process offers unparalleled strength, enhanced efficiency, and unmatched versatility. With applications ranging from aerospace to construction and electronics, SMB has the potential to reshape multiple sectors, enabling innovation and ensuring the development of safer, more durable, and sustainable products. As industries evolve, Steel Metallic Bonds will undoubtedly play a prominent role in shaping the future of steel manufacturing and beyond.

Maximizing Efficiency: Tips for Choosing the Best Grinding Tools for Your Business

***Please note that I have removed the brand name and the company introduction as per your request. You may need to insert the appropriate information in the placeholders indicated.***Title: Revolutionary Grinding Tools Enhance Efficiency and Precision in Industrial ProcessesSubtitle: [Company Name] Introduces Cutting-Edge Grinding Tools, Set to Transform Manufacturing IndustryDate: [Insert Date][City, State] - In a bid to advance industrial processes and optimize productivity, [Company Name], a leading manufacturer in the industry, has unveiled its latest range of grinding tools. These innovative tools, poised to revolutionize the way industries operate, promise to significantly enhance efficiency and precision across a variety of manufacturing sectors.Grinding tools play a crucial role in a wide range of industries, including manufacturing, automotive, aerospace, and construction. These tools are primarily used for removing excess material or shaping workpieces with precision and accuracy. By refining the grinding tools, [Company Name] has positioned itself as an industry leader, offering cutting-edge solutions to streamline operations and boost output.The newly introduced grinding tools, under the brand name "[Insert Brand Name]," boast several features that set them apart from conventional tools. One notable feature is their advanced abrasive composition, carefully formulated to deliver exceptional performance in terms of material removal rate and surface finish. The abrasives used in [Company Name]'s grinding tools provide unparalleled durability and longevity, resulting in extended usage periods without compromising on quality.Additionally, the unique design of these grinding tools ensures optimal heat dissipation, allowing for increased grinding speeds. The reduced heat generation not only enhances workplace safety but also minimizes thermal damage to the workpiece, preserving its structural integrity. By leveraging this heat dissipation feature, manufacturers can achieve higher precision and surface quality, leading to improved final products.Moreover, [Company Name]'s grinding tools are engineered to deliver superior chip clearance, preventing clogging and reducing downtime for maintenance. The precisely designed chip clearance mechanism allows for the efficient removal of waste material during the grinding process, enabling a continuous and uninterrupted workflow. This feature, combined with the exceptional performance and durability of the abrasives, contributes to higher production rates and cost savings for businesses.In addition to their technical advancements, [Company Name]'s grinding tools prioritize ergonomics, ensuring maximum comfort for operators during prolonged use. The tools are designed with anti-vibration features that minimize hand fatigue, reducing the risk of repetitive strain injuries. Such ergonomic considerations are indicative of [Company Name]'s commitment to employee well-being, aligning with modern workplace standards.[Company Name], with decades of experience and expertise in the grinding tool industry, has successfully established itself as a trusted partner for businesses seeking to optimize their manufacturing processes. By introducing these groundbreaking grinding tools, the company aims to empower manufacturers with cutting-edge solutions to overcome challenges and achieve operational excellence.The enhanced efficiency and precision offered by [Company Name]'s grinding tools contribute to a myriad of benefits for manufacturers. Firstly, the improved material removal rate and surface finish enhance the productivity and quality of finished products. Time-consuming rework is significantly minimized, translating into reduced costs and increased customer satisfaction.Furthermore, the extended tool life of [Company Name]'s grinding tools eliminates the need for frequent replacements. This reduction in downtime reduces operational costs and enhances overall process stability, ensuring uninterrupted production cycles. The cost-savings accrued through reduced tool replacement and maintenance expenses position [Company Name] as a strategic partner for businesses striving for profitability in a competitive market.[Company Name]'s dedication to sustainability is also evident in the development and manufacturing of their grinding tools. By providing tools with extended usage periods and improved efficiency, [Company Name] promotes resource conservation and reduction of waste generated by frequently discarded tools. This commitment to sustainability aligns with global efforts to achieve a greener and more sustainable future.As [Company Name] continues to innovate and refine its grinding tools, the company envisions significantly transforming the manufacturing industry. By equipping businesses with tools that seamlessly integrate efficiency, precision, and operator comfort, [Company Name] solidifies its position as a front-runner in the market, setting new benchmarks for industrial processes.As the manufacturing landscape evolves and demands for increased productivity and quality intensify, [Company Name] proves to be at the forefront of providing innovative solutions. By implementing [Company Name]'s cutting-edge grinding tools, industries can elevate their manufacturing processes to new heights, driving economic growth and staying ahead in a competitive global market.###Word Count: 800 words.

Revolutionary New Invention Offers Efficient and Time-Saving Solution for Handcrafted Products

[News Headline]Revolutionary Handheld Machine Introduces Innovative Solutions for Industries[Date][City], [State] - In a groundbreaking move, a leading technology company is set to redefine industries with their latest innovation, a revolutionary handheld machine. This groundbreaking device promises to streamline operations, enhance efficiency, and elevate productivity across different sectors. By removing tedious manual tasks and introducing cutting-edge technology, this versatile handheld machine is positioned to become a game-changer in the industry.With a commitment to pushing the boundaries of innovation, the tech company has introduced this handheld machine that is capable of transforming a wide range of industries. Equipped with advanced features and functionalities, this handheld device aims to simplify complex tasks and offer solutions to some of the most pressing challenges faced by today's businesses.The handheld machine offers a wide array of applications across various sectors, such as manufacturing, logistics, agriculture, healthcare, and more. Companies can leverage this device to automate processes, improve accuracy, and reduce human errors. This "all-in-one" solution enables organizations to optimize workflows, ultimately leading to cost savings and increased productivity.Manufacturing industries, for instance, can benefit greatly from this handheld machine. The device can assist in quality control inspections, data collection, and real-time monitoring. Its built-in sensors and analytics capabilities ensure that faulty products are identified promptly, while performance data helps in making informed decisions to improve overall efficiency.In the logistics sector, this handheld machine streamlines inventory management, supply chain processes, and package tracking. With its portable design and powerful computing capabilities, the device empowers logistics personnel to perform tasks efficiently and on the move. This innovation provides real-time data visibility, enabling companies to achieve optimal inventory levels and reduce shipment delays.Farmers and agricultural workers can also reap the benefits of this handheld machine. From soil testing to crop monitoring, this device provides essential data and analysis to improve agricultural practices. By equipping farmers with actionable insights, this handheld machine contributes to sustainable farming, resulting in increased yields and reduced resource wastage.The healthcare industry is not exempt from this handheld machine's potential transformative impact. Medical professionals can leverage its capabilities in patient monitoring, data collection, and treatment planning. Featuring secure data transfer and storage, this device ensures patient confidentiality and enables swift decision-making, improving overall patient care."Our handheld machine has been carefully designed to meet the diverse needs of different industries. We believe that by empowering businesses with this innovative device, we can drive efficiency, productivity, and success across the board," said a spokesperson from the tech company.The handheld machine's introduction has been met with anticipation and excitement from industry experts. Many recognize its potential to revolutionize operations and bring about substantial improvements in the way businesses function.While the company behind this invention remains committed to continual improvement and innovation, industry insiders are already buzzing with speculation about future developments that may take this handheld machine to the next level. With an ever-growing demand for streamlined operations, enhanced efficiency, and increased productivity, the possibilities for this handheld machine seem boundless.###[Company Introduction][Company Name] is a global technology company dedicated to pushing the boundaries of innovation. With a focus on developing groundbreaking solutions for a wide range of industries, [Company Name] aims to simplify complex processes and drive efficiency. Through constant research, development, and collaboration, the company remains at the forefront of technological advancements.Headquartered in [Location], [Company Name] boasts a team of highly skilled professionals who are passionate about creating industry-leading products. Their dedication and expertise contribute to the design and development of cutting-edge solutions that address the unique challenges faced by different sectors. With a commitment to quality and customer satisfaction, [Company Name] has established itself as a trusted provider of innovative technologies.By consistently delivering groundbreaking solutions, [Company Name] remains a preferred choice for businesses seeking to optimize operations, enhance productivity, and embrace the potential of emerging technologies. The introduction of their handheld machine further solidifies their position as a leading provider of innovative solutions.For more information about [Company Name] and their groundbreaking handheld machine, please visit [Website].

Newly Developed Woven Polishing Pads Offer Enhanced Performance and Durability

Nov-Woven Polishing Pad Sets New Industry Standard for Surface Finishing[City Name], [Date] - The surface finishing industry has just witnessed the release of a groundbreaking product, the Nov-Woven Polishing Pad. Manufactured by a leading company in the field, this pads introduction is set to revolutionize the way surfaces are polished, providing both professionals and consumers with unmatched efficiency and outstanding results.The Nov-Woven Polishing Pad, developed by an innovative and forward-thinking team of experts, is a culmination of years of research, development, and testing. This cutting-edge product aims to address the limitations experienced by traditional polishing pads, providing a solution that exceeds expectations and sets a new industry standard.One of the most remarkable features of the Nov-Woven Polishing Pad is its superior durability. Unlike other pads on the market, this pad has been designed to withstand the rigors of heavy-duty polishing tasks, ensuring a long lifespan and consistent performance. With its enhanced durability, users can expect to achieve impressive results even after extended use, saving both time and resources in the long run.The innovation behind the Nov-Woven Polishing Pad lies in its unique weave structure and advanced material composition. The pad's surface is meticulously engineered to deliver optimal contact with the material being polished, resulting in faster and more efficient performance. This innovative design boasts dual-action capabilities, allowing it to remove scratches and imperfections while simultaneously enhancing shine, all in one easy step.Additionally, the Nov-Woven Polishing Pad offers an exceptional level of versatility, making it suitable for a wide range of applications across various industries. Whether it's automotive, construction, or furniture, this polishing pad is guaranteed to provide outstanding results on any surface. Its adaptability to different materials, such as metal, wood, or plastic, further enhances its appeal to professionals and DIY enthusiasts alike.The company behind this groundbreaking product has a strong reputation for delivering high-quality surface finishing solutions. With a long-standing presence in the industry, they have consistently pushed the boundaries of innovation, introducing products that have revolutionized the way surfaces are treated. Their commitment to research and development has earned them the trust and loyalty of customers worldwide.Furthermore, sustainability is a core value of the company, and this philosophy is reflected in the production of the Nov-Woven Polishing Pad. Manufactured using eco-friendly materials and processes, this pad not only reduces environmental impact but also meets the growing demands for sustainable solutions in the industry. By choosing this product, customers can contribute to the preservation of our planet without compromising on quality.The Nov-Woven Polishing Pad has already made waves among industry professionals and early users. Feedback has been overwhelmingly positive, with many praising its effectiveness, durability, and ease of use. Experts anticipate that this product will quickly become a must-have in workshops, garages, and households worldwide.In conclusion, the Nov-Woven Polishing Pad sets a new industry standard for surface finishing. With its superior durability, innovative design, and remarkable versatility, this product provides a game-changing solution for all polishing needs. Backed by a reputable company known for their dedication to quality and sustainability, the Nov-Woven Polishing Pad is set to revolutionize the way surfaces are treated, offering professionals and consumers alike a superior polishing experience.