Understanding the Strength and Characteristics of Metallic Bonds in Steel

Title: Groundbreaking Innovation in Metal Bonding Techniques Unveiled by Leading Manufacturer Introduction: In a revolutionary leap forward, a prominent manufacturer in the metal industry has developed an advanced metal bonding technique that promises to redefine the world of steel manufacturing. By leveraging cutting-edge technology and expertise, this innovative process aims to enhance the efficiency, strength, and versatility of metallic bonding, opening up new possibilities across various industries. Read on to discover how Steel Metallic Bonds (SMB), a pioneering metal bond solution, is set to transform the manufacturing landscape.1. The Evolution of Metallic Bonding Techniques:Since the advent of metallurgy, researchers and manufacturers have constantly pursued improved ways to bond metal materials. Conventional welding and adhesive bonding techniques have served as the backbone of metal fabrication for centuries. However, with the introduction of SMB technology, a seismic shift in the way metals are joined is on the horizon.2. The Science Behind Steel Metallic Bonds (SMB):Steel Metallic Bonds (SMB) is a state-of-the-art metal bonding technology that relies on a unique chemical process and advanced robotics. The process involves the formation of interatomic bonding between metal particles, resulting in an incredibly strong bond that surpasses traditional joining methods. This breakthrough technique allows for precise control of bond strength and ensures uniform distribution of stress, circumventing weak points and vulnerabilities.3. Key Advantages of Steel Metallic Bonds:i. Unparalleled Strength: SMB generates bonds with exceptional strength and durability, making it ideal for high-stress applications such as aerospace, automotive, and construction. The uniform distribution of stress allows for enhanced load-bearing capabilities, contributing to the overall safety and longevity of the final product.ii. Enhanced Efficiency: Unlike conventional methods such as welding, SMB eliminates the need for melting and fusion, significantly reducing energy consumption and production time. Faster production cycles translate into improved cost-efficiency, making SMB an attractive choice for manufacturers looking to streamline their operations.iii. Versatility: Steel Metallic Bonds offer unmatched versatility, enabling the bonding of different metals and alloys that were previously considered incompatible. This breakthrough technology opens up new design possibilities and materials combinations, fostering innovation across industries.iv. Corrosion Resistance: One of the notable advantages of SMB is its inherent resistance to corrosion. By minimizing the presence of exposed areas in the bonded joints, this innovative technique provides an added layer of protection against environmental factors, ultimately extending the lifecycle of metal structures.4. Applications Across Industries:i. Aerospace: Steel Metallic Bonds offer aerospace manufacturers the opportunity to develop lighter, stronger, and more fuel-efficient aircraft. By replacing traditional rivets and welding techniques, SMB enables the creation of seamless structures with improved aerodynamic properties.ii. Automotive: In the automotive sector, SMB unlocks new possibilities for lightweight designs, contributing to better fuel efficiency and reduced emissions. Additionally, the enhanced bonding strength ensures the structural integrity of various components, improving overall safety.iii. Construction: Steel Metallic Bonds revolutionize the construction industry by offering builders the ability to create stronger and more resilient structures. From skyscrapers to bridges, this breakthrough technology ensures strength, durability, and resistance to external forces, resulting in safer buildings with extended lifespans.iv. Electronics: The precise control over bonding strength and the ability to join dissimilar metals make SMP an ideal solution for the electronics industry. This technology holds the potential to revolutionize electronic packaging, improving heat dissipation, reducing size, and enhancing product performance.Conclusion: The advent of Steel Metallic Bonds (SMB), a cutting-edge metal bonding solution, marks a groundbreaking milestone in the manufacturing industry. By combining advanced chemistry, robotics, and engineering, the SMB process offers unparalleled strength, enhanced efficiency, and unmatched versatility. With applications ranging from aerospace to construction and electronics, SMB has the potential to reshape multiple sectors, enabling innovation and ensuring the development of safer, more durable, and sustainable products. As industries evolve, Steel Metallic Bonds will undoubtedly play a prominent role in shaping the future of steel manufacturing and beyond.

Read More

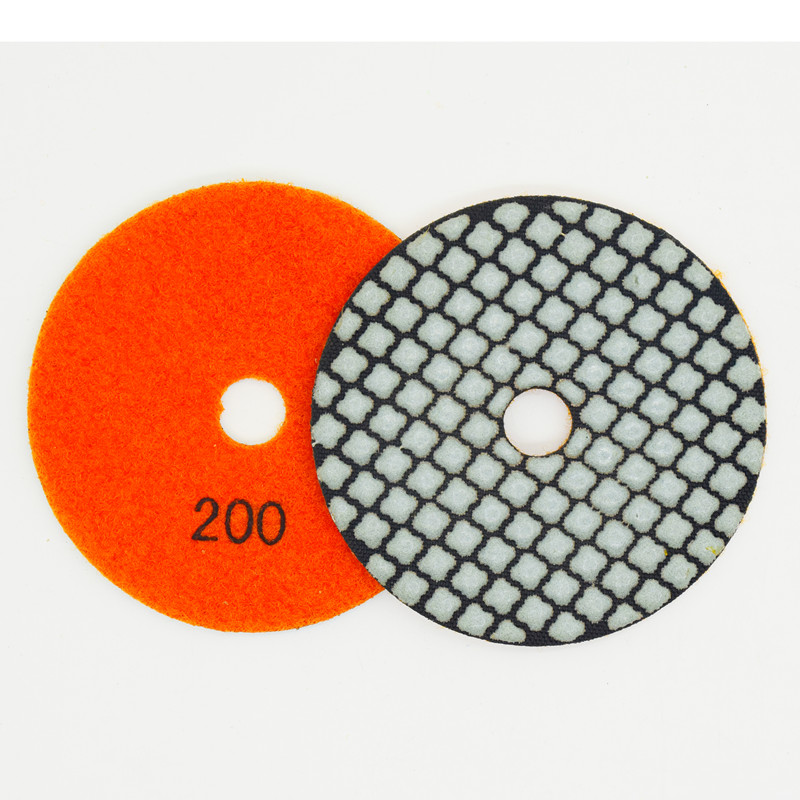

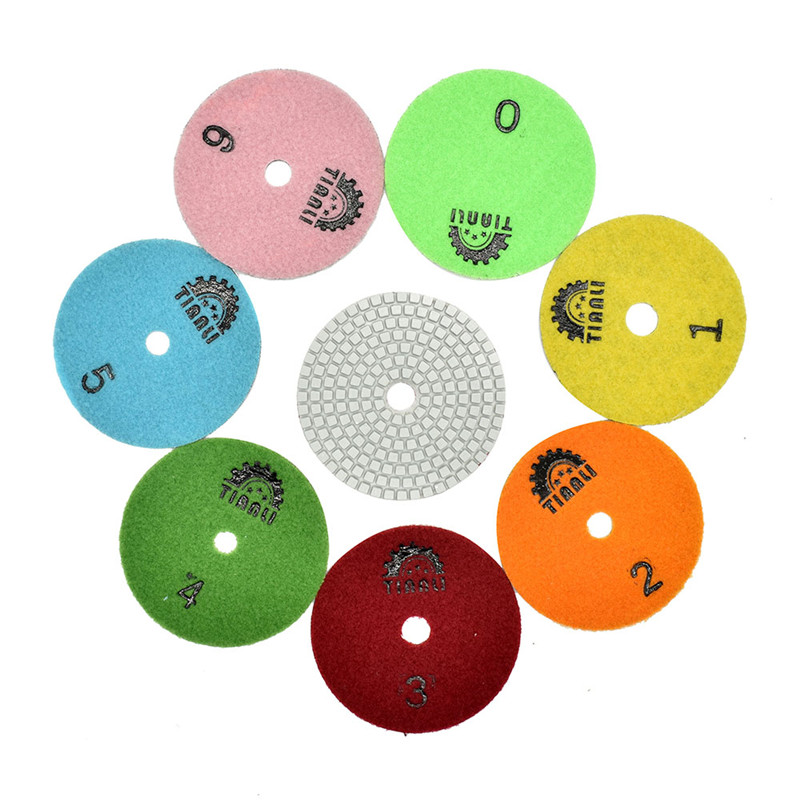

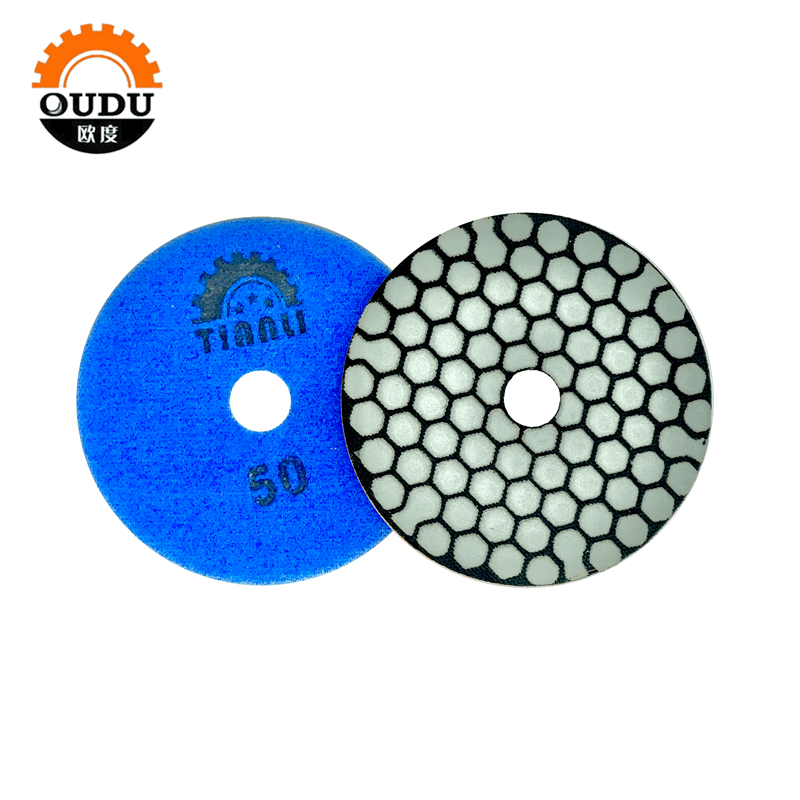

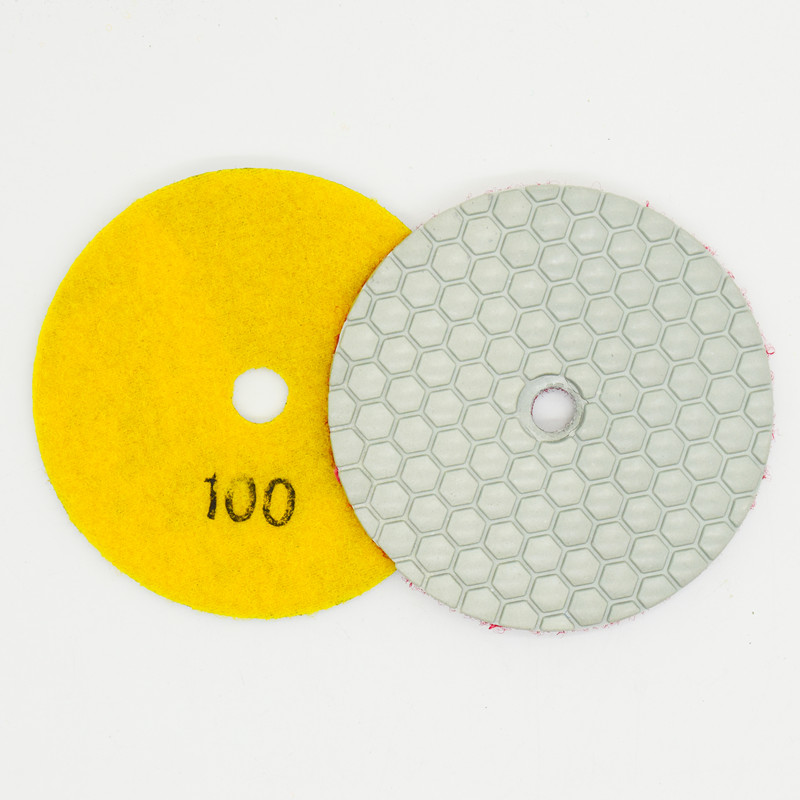

Dry Polishing Pads for Diamond Resin Surfaces

Title: Revolutionary Diamond Resin Dry Polishing Pads Transform Surface Finishing IndustryIntroduction, a leading innovator in surface finishing technologies, has recently unveiled its latest breakthrough product, the Diamond Resin Dry Polishing Pads. This revolutionary solution is set to transform the surface finishing industry by providing an unprecedented level of efficiency, effectiveness, and durability. With its cutting-edge design and advanced materials, the Diamond Resin Dry Polishing Pads offer an unmatched polishing experience, catering to a wide range of applications across various industries.I. BackgroundSurface finishing plays a crucial role in enhancing the aesthetic appeal and functionality of a wide array of surfaces, including natural stones, engineered stones, ceramics, concrete, and more. Traditionally, wet polishing has been the go-to method for achieving a high-quality finish. However, this process comes with several drawbacks, such as a messy working environment, longer processing times, and potential water-related damages. Recognizing these challenges, embarked on a mission to revolutionize the industry by developing a dry polishing solution that overcomes these limitations.II. Diamond Resin Dry Polishing Pads: The Game-ChangerThe Diamond Resin Dry Polishing Pads from are engineered using state-of-the-art technology and the finest diamond particles, resulting in an exceptional product that truly stands out in the market. These pads offer an innovative alternative to traditional wet polishing methods, eliminating the need for water during the grinding and polishing process.1. Unparalleled EfficiencyUnlike wet polishing pads, the Diamond Resin Dry Polishing Pads feature a unique design that maximizes surface contact while minimizing friction and heat buildup. This design allows for faster material removal, significantly reducing processing times. Moreover, the absence of water ensures a clear field of vision, enabling operators to closely monitor the progress and achieve precise results with ease.2. Superior PerformanceThe advanced diamond particles embedded in the resin matrix ensure exceptional cutting power and abrasion resistance. This enables the Diamond Resin Dry Polishing Pads to deliver unparalleled shine and clarity on a wide range of materials. Whether it is granite, marble, quartz, or concrete, these pads consistently produce remarkable results, exceeding industry standards.3. Enhanced Durability's Diamond Resin Dry Polishing Pads are engineered for longevity and consistent performance. The high-density resin matrix, combined with the premium diamond particles, offers exceptional durability, reducing the need for frequent pad replacements. This not only saves costs but also increases productivity by reducing downtime associated with changing pads.III. Applications Across IndustriesThe versatility of the Diamond Resin Dry Polishing Pads makes them suitable for an array of applications across various industries:1. Construction and Architecture: The pads provide a flawless finish to natural stone countertops, flooring, and decorative elements.2. Manufacturing: Engineered stone surfaces, such as quartz countertops, can achieve outstanding shine and smoothness with ease.3. Automotive and Aerospace: Polishing pads are essential for finishing automotive body panels, composite materials, and aircraft parts.4. Restoration and Maintenance: The Diamond Resin Dry Polishing Pads effectively restore and maintain existing surfaces, breathing new life into dull or damaged materials.IV. Environmental and Cost BenefitsThe adoption of 's Diamond Resin Dry Polishing Pads brings several environmental and cost-saving advantages:1. Water Conservation: Eliminating the need for water reduces water consumption in surface polishing processes, contributing to sustainable practices.2. Cleaner Workspace: The dry polishing method ensures a cleaner working environment, minimizing mess and reducing the time required for post-processing cleanup activities.3. Lower Costs: Faster processing times, reduced material wastage, and enhanced pad durability result in lower operational costs and increased profitability for businesses.V. Conclusion's Diamond Resin Dry Polishing Pads mark a significant milestone in surface finishing techniques, revolutionizing the industry by offering unparalleled efficiency, superior performance, and enhanced durability. With their wide range of applications and numerous environmental and cost-saving benefits, these pads are set to become the new standard in surface finishing technologies.

Read More

Discover the Ultimate Grinding Wheels for Diamond and CBN Applications

Title: Industry-Leading Diamond CBN Grinding Wheels Revolutionary Solution for Superior PerformanceIntroduction: In today's fast-paced industrial landscape, the demand for high-performance grinding solutions has reached new heights. Leading the charge is a renowned company, specializing in developing and manufacturing advanced tools for all industries, including the groundbreaking Diamond CBN Grinding Wheels. Recognized for their innovative approach and dedication to delivering exceptional quality products, this company has revolutionized the grinding wheel industry.With an unwavering commitment to excellence and decades of experience, has become a trusted name in the manufacturing sector, setting the benchmark for precision and efficiency. The latest offering, their Diamond CBN Grinding Wheels, showcases their expertise and determination to deliver game-changing solutions that surpass customer expectations.Superior Manufacturing Process:The Diamond CBN Grinding Wheels offered by leverage the cutting-edge technology and expertise of the company. Through extensive research and development, they have achieved a manufacturing process that combines diamond and cubic boron nitride (CBN) to create a wheel that excels at grinding various materials.Diamond and CBN are two of the hardest known substances, offering extraordinary wear resistance. By utilizing these materials in their grinding wheels, ensures exceptional durability and extended operational lifespan. This unique combination enables these wheels to withstand high abrasion and heat generated during the grinding process, providing a reliable and consistent performance.Unmatched Versatility:One of the key attributes of the Diamond CBN Grinding Wheels is their unmatched versatility. Designed to excel across a wide range of grinding applications, these wheels are suitable for both wet and dry grinding processes. This flexibility allows various industries, including automotive, aerospace, and precision tool manufacturers, to benefit from the superior grinding capabilities provided by .Unrivalled Precision and Consistency:The precise manufacturing process employed by contributes to the diamond CBN grinding wheels' ability to achieve high-level accuracy and consistency. With their uniformity in grit distribution, these wheels offer precision grinding results, minimizing material wastage and enabling manufacturers to achieve tight tolerances in their products.Furthermore, due to the exceptional wear resistance properties of diamond and CBN, these wheels retain their shape and sharpness for longer periods, resulting in consistent grinding performance throughout their lifespan. This consistency ensures repeatable and reliable results for industries that demand the highest standards of quality and accuracy.Reduced Operational Costs:The innovative design of 's Diamond CBN Grinding Wheels benefits manufacturers in various ways, including cost reduction. These wheels' extended operational lifespan significantly reduces the frequency of wheel replacements, resulting in reduced downtime and increased productivity. Additionally, their exceptional material removal rates enable faster grinding, enhancing overall efficiency and reducing labor costs.Safety and Environmentally Conscious:In addition to their outstanding performance, the Diamond CBN Grinding Wheels prioritize safety and environmental considerations. The company adheres to strict quality control measures during the manufacturing process, ensuring that each wheel meets the highest safety standards. Additionally, these wheels generate fewer sparks during grinding, reducing the risk of workplace accidents, while minimizing the impact on the environment.Conclusion:Through the introduction of their Diamond CBN Grinding Wheels, has once again cemented their position as an industry leader, providing cutting-edge solutions to meet the evolving demands of various sectors. By harnessing the extraordinary attributes of diamond and CBN, has developed a product that offers unmatched grinding performance, exceptional durability, precision, versatility, and cost-effectiveness.As industries continue to strive for innovation and optimization, the Diamond CBN Grinding Wheels offered by remain at the forefront as a choice for manufacturers seeking superior grinding solutions. With their commitment to excellence and passion for engineering advancements, continues to pave the way for the future of grinding technology.

Read More

Unlocking the Mystery of Gold's Metallic Bonds: A Fascinating Study Reveals Intriguing Properties

Title: Advancements in Metallic Bond Technology Unveiled by Industry LeaderIntroduction:In a dynamic and ever-evolving industry, the field of metallic bonding has witnessed significant advancements with the introduction of a groundbreaking technology by a leading company. This groundbreaking innovation, known as Gold Metallic Bonds (GMB), aims to revolutionize various sectors that heavily rely on the inherent properties of metallic bonding. With its unique characteristics and applications, GMB holds the potential to transform industries such as electronics, energy, automotive, and aerospace.I. Understanding Gold Metallic Bonds:Historically, metallic bonds have been crucial in facilitating the formation of metallic solids. They involve the sharing of delocalized electrons among a lattice of positively charged metal ions, resulting in a highly conductive and malleable material. With Gold Metallic Bonds, this classic form of bonding takes a leap forward by incorporating gold as a key component in the bonding process. Gold, renowned for its exceptional conductivity and corrosion resistance, enhances the inherent properties of the metallic bond, opening up new possibilities for technological breakthroughs.II. Enhanced Conductivity for Electronics Industry:In the realm of electronics, Gold Metallic Bonds prove to be invaluable. As the demand for faster and more efficient electronic devices continues to rise, GMB can greatly enhance conductivity, leading to improved performance. By incorporating GMB into circuitry, transmission speeds can be significantly enhanced, minimizing data loss and optimizing overall device functionality. Moreover, this technology offers increased resistance to corrosion, ensuring longevity and reliability in electronic components.III. Addressing Energy Efficiency Challenges:The energy sector is another industry that stands to benefit from Gold Metallic Bonds. With the growing focus on renewable energy sources, GMB can aid in increasing conversion efficiency and reducing energy loss. From solar panels to wind turbines, GMB utilization can enhance energy capture and transfer mechanisms, enabling the generation of cleaner, more sustainable power. Additionally, GMB's corrosion resistance properties contribute to prolonged equipment life, lowering maintenance costs and improving overall efficiency.IV. Reinventing Automotive Engineering:In the automotive industry, safety and performance are paramount. Gold Metallic Bonds can redefine vehicle engineering by improving structural integrity and crashworthiness. The inclusion of GMB in critical components, such as chassis frames and safety structures, significantly enhances the material's strength, leading to more robust and safer vehicles. Furthermore, GMB's conductivity also invites advancements in the electric vehicle domain, allowing for better battery performance and efficient power delivery.V. Aiding Aerospace Applications:The aerospace industry also stands to benefit from Gold Metallic Bonds, particularly in aircraft design and construction. The lightweight and high-strength properties of GMB make it an ideal candidate for applications like airframes and turbine engines. With GMB, aerospace manufacturers can achieve weight reduction without sacrificing structural integrity, leading to improved fuel efficiency and longer range capabilities. Moreover, GMB's resistance to corrosion ensures durability in harsh environments, increasing aircraft lifespan and reducing maintenance costs.Conclusion:The introduction of Gold Metallic Bonds marks a significant milestone in the field of metallic bonding technology. With its unique properties, GMB has the potential to revolutionize a multitude of industries, including electronics, energy, automotive, and aerospace. Through enhanced conductivity, increased corrosion resistance, and improved structural integrity, GMB can pave the way for technological advancements that improve efficiency, safety, and sustainability. As companies continue to explore the vast potential of Gold Metallic Bonds, a new era of innovation and progress beckons, promising transformative changes across various sectors.

Read More

Efficient and Professional Wood Floor Sanding Edging Machine for Flawless Results

Wood Floor Sanders Are Evolving with New Technologies to Enhance PerformanceFlooring is an essential component of any building, providing a comfortable, appealing, and secure surface for homeowners and occupants. Wood flooring, in particular, has always been a popular choice for homeowners due to its durability, longevity, and elegance. However, like any other flooring material, wood flooring is not immune to wear and tear. Over time, it may develop scratches, unevenness, and other imperfections that can mar its beauty and functionality.Thankfully, wood floor sanding has emerged as a reliable way to restore wooden floors to their former glory. Sanding involves using abrasive materials to remove the top layer of the wood flooring, eliminating any imperfections and creating a smooth and even surface. However, sanding is a labor-intensive and time-consuming process that can take several days to complete, depending on the area's size. In addition, sanding can expose the wood to potential damages due to incorrect sanding techniques.To counteract these challenges, manufacturers are continually seeking new technologies and innovations to enhance wood sanding's efficiency and effectiveness. One such innovation is the Wood Floor Sanding Edging Machine, specially designed to remove the toughest of stains and imperfections that hand sanding may miss.This machine is excellent for edging, baseboard sanding, and final sanding, thanks to its powerful motor and ergonomic design. Unlike traditional sanders that require manual labor to move the machine around the working surface, this machine has an extended handle, making it easy to maneuver around the edge of the flooring without bending or crouching. Its high power output also ensures that it efficiently grinds off any rough spots, ensuring a smooth and even finish.Additionally, the wood sanding machine is equipped with dust retention technology that significantly minimizes dust generated during sanding. This is essential not only for the health and safety of those around the working area but also prevents the dust from settling back on the floor, ruining the final finish.The Wood Floor Sanding Edging Machine is versatile in use, making it an ideal choice for both commercial and residential sectors. It can easily shift from one area to another, making it an excellent investment for experts seeking efficient and cost-effective sanding solutions. It can also be used for site-specific sanding requirements, such as concrete or wood floors.When it comes to choosing the right wood floor sanding edging machine, industry professionals need to identify specific requirements and select a machine that best suits their needs. This includes evaluating the machine's power, sanding disc size, weight, compatibility with existing sanding equipment, and dust collection mechanism.In conclusion, wood floor sanding has become an essential practice to maintain the beauty and durability of wood flooring. With the use of modern technologies and innovations, such as the Wood Floor Sanding Edging Machine, professionals can now sand wooden floors more efficiently, effectively, and safely. Whether you're a flooring contractor, renovation expert, or a DIY homeowner, investing in this cutting-edge sanding machine can help make your wood flooring projects a resounding success.

Read More

Discover the Versatility of Angle Grinder Nylon Cup Brushes with this Handy Guide

A new nylon cup brush for angle grinders has been introduced into the market, offering superior performance for surface cleaning and rust removal. This product is set to revolutionize the manufacturing process of various industries by providing an efficient and cost-effective solution for removing rust and eliminating surface contamination.This innovative tool is suitable for cutting, sanding, and polishing surfaces made of metal, wood, and plastic, among others. Unlike traditional wire brushes that can leave scratches on metal surfaces, the nylon cup brush is made of fine nylon bristles that produce a flawless surface finish. Additionally, the brush is designed to work on high-speed angle grinders, making it perfect for industrial applications.The nylon cup brush is a product of an experienced and reputable company that is well-known for its quality products. According to the company's introduction, the nylon cup brush is made using a unique manufacturing process that ensures superior quality and durability. Additionally, the company has incorporated advanced technology in the design of this brush, making it versatile and reliable.The nylon cup brush is easy to use, making it perfect for both professional use and DIY enthusiasts. To use the brush, simply attach it to your angle grinder and let the machine do the work. The advanced design of the brush ensures that it removes rust and cleans surfaces quickly and efficiently. This significantly reduces the time and effort required for surface preparation and finishing.In addition to being efficient and effective, the nylon cup brush is also environmentally friendly. The brush is made of nylon, a material that is recyclable and has a low carbon footprint. This makes it an ideal alternative to traditional wire brushes that are known to leave behind metal shavings and can be harmful to the environment.The introduction of the nylon cup brush to the market is a significant development that will benefit various industries. This includes automotive, construction, and manufacturing. The brush is expected to improve the productivity of businesses by reducing the time and effort required for surface preparation and finishing. Additionally, the brush is cost-effective, making it an ideal solution for businesses looking to reduce their operating costs.The nylon cup brush is also ideal for DIY projects at home. Its ease of use and efficiency make it perfect for removing rust from automotive parts and cleaning up surfaces around the home. Moreover, the brush is affordable, making it accessible to homeowners who want to undertake DIY projects.In summary, the introduction of the nylon cup brush to the market is an exciting development that has the potential to revolutionize the surface cleaning and rust removal industry. The brush is made of fine nylon bristles that provide a perfect surface finish and is designed to work with high-speed angle grinders, making it perfect for industrial applications. Additionally, the brush is environmentally friendly, cost-effective, and easy to use. As such, it is expected to benefit various industries, including automotive, construction, and manufacturing, as well as homeowners undertaking DIY projects.

Read More

Scientists Discover New Metal Carbon Bonds with Potential Applications in Medicine and Industry

[Company Introduction]{Company Name} is a leading, innovative organization specializing in advanced materials and chemical research and development. With a mission to revolutionize industries through groundbreaking discoveries, the company has consistently pushed the boundaries of science and technology. Focused on improving various sectors, such as energy, electronics, and healthcare, {Company Name} is proud to announce its latest breakthrough in the field of metal carbon bonds.[News Content]{City Name}, {Date} - {Company Name}, an esteemed pioneer in advanced materials research, has recently unveiled a groundbreaking discovery in the realm of metal carbon bonds, hailing a new era of possibilities for several industries.The research team at {Company Name} has successfully developed a novel metal carbon bond material that exhibits exceptional properties, including remarkable stability, high conductivity, and great versatility. This discovery is expected to significantly impact multiple sectors, ranging from electronics and renewable energy to pharmaceuticals and catalysis.Metal carbon bonds, extensively utilized in a wide array of applications, have long been regarded as a critical component in various industries. However, traditional metal carbon bond materials suffer from limitations, such as poor durability and limited functionality. Recognizing the immense potential for improvement, {Company Name} embarked on an extensive research program to redefine metal carbon bonds.After years of dedicated efforts, {Company Name}'s research team has successfully synthesized an innovative metal carbon bond material that overcomes these limitations. The material, which remains undisclosed due to Patent and Intellectual Property considerations, offers unprecedented chemical stability, enabling its application in numerous corrosive environments. Furthermore, it possesses superior electrical conductivity, making it ideal for electronic components.The versatility of this breakthrough is striking, paving the way for its implementation in diverse fields. One potential application lies in the renewable energy sector, where the conductive properties of this material can enhance the efficiency of solar cells, leading to increased power generation. Additionally, it could revolutionize energy storage technologies, improving the performance of batteries and unlocking new energy storage solutions.Moreover, the pharmaceutical industry stands to benefit immensely from this development. This novel metal carbon bond material can be utilized in drug delivery systems, ensuring precise and controlled release of therapeutic agents. Furthermore, the improved stability of the material enhances drug stability, reducing the need for extensive storage precautions.The electronics industry is also poised to undergo a transformative change. {Company Name}'s metal carbon bond material offers promise for ultrafast, high-performance microchips and next-generation electronic devices. Its exceptional conductivity and stability can enable the development of smaller, more efficient electronics, revolutionizing the consumer electronics market.In summary, {Company Name}'s groundbreaking discovery in metal carbon bonds marks a significant milestone in materials science. This breakthrough materializes a paradigm shift, ensuring enhanced performance across various sectors. The potential applications in renewable energy, pharmaceuticals, and electronics are just the tip of the iceberg, as further research and development will inevitably unveil hitherto unexplored possibilities.{Company Name} intends to collaborate with industry partners, academia, and research institutions to expedite the translation of this innovative material into commercial products. The future holds immense promise as this groundbreaking discovery paves the way for a new generation of advanced materials, revolutionizing industries and shaping a brighter future.

Read More

Top-rated Environmental-friendly Cleaning Machine Revolutionizes Industries

As the world continues to grapple with the COVID-19 pandemic, there has been an increase in demand for cleaning and disinfection products. Clean Machine, a leading provider of cleaning solutions, has stepped up to the challenge, providing high-quality products that are effective against the virus.Clean Machine has been in the cleaning business for over 20 years. The company has a reputation for providing innovative cleaning solutions that are both eco-friendly and cost-effective. The company offers a wide range of cleaning products, including hand sanitizers, disinfectants, and degreasers.One of Clean Machine's flagship products is the disinfectant spray. This product has been specifically designed to kill germs, bacteria, and viruses, including the COVID-19 virus. The disinfectant spray is easy to use and can be used on a wide range of surfaces, including countertops, floors, and walls.Another popular product from Clean Machine is the hand sanitizer gel. This product has been formulated to kill germs on the hands, providing a convenient and effective way to keep hands clean and germ-free. The hand sanitizer gel is available in different sizes, making it suitable for use at home, in the office, or when traveling.Clean Machine prides itself on its commitment to sustainability. The company's products are manufactured using eco-friendly ingredients that are safe for both humans and the environment. The products are also packaged in recyclable materials, further reducing their impact on the environment.In addition to its commitment to sustainability, Clean Machine is also committed to providing exceptional customer service. The company's customer support team is available to answer any questions and provide advice on the best products for specific cleaning needs. Clean Machine also offers training and support to its customers, ensuring that they get the most out of the products they purchase.Clean Machine's dedication to quality and sustainability has earned the company a loyal customer base. Many businesses and households have turned to Clean Machine for their cleaning needs, especially during the pandemic. The company has also received positive reviews from customers who have praised the effectiveness of its products.As the world continues to battle the COVID-19 pandemic, Clean Machine remains committed to providing effective and sustainable cleaning solutions. The company continues to innovate and develop new products that are designed to kill germs and keep people safe. With its focus on sustainability, quality, and exceptional customer service, Clean Machine is poised to continue leading the way in the cleaning industry.

Read More

Top 7 Inch Grinding Wheel: Essential Tool for Precision and Efficiency

Title: High-Quality 7-Inch Grinding Wheel Now Available for Enhanced Precision and EfficiencyIntroduction:In a recent development, a renowned company, specializing in industrial tools and machinery, has released its latest offering - a top-notch 7-inch grinding wheel. Designed to deliver superior performance, this all-new grinding wheel promises enhanced precision and efficiency. The company, known for its commitment to quality and innovation, has once again raised the bar in the field of industrial abrasives.[Company Name - OPTIONAL]:With over [number of years] of experience, and a strong presence in the industrial sector, this company has become a trusted name for professionals and hobbyists alike. Established with the goal of providing cutting-edge tools and machinery, the company has consistently delivered products that exceed the expectations of its customers. Renowned for its commitment to quality, reliability, and customer satisfaction, the company continues to be a prominent player in the industry.The 7-Inch Grinding Wheel:The newly launched 7-inch grinding wheel is the result of extensive research and development efforts by the company's team of experts. Crafted with precision, the wheel offers exceptional durability and performance, making it an ideal choice for various grinding applications. Equipped with advanced features, this grinding wheel ensures an efficient workflow while adding a touch of convenience to the user's experience.The key features of the 7-inch grinding wheel include:1. High-Quality Materials: Crafted from premium-grade materials, this grinding wheel offers excellent durability and long-lasting performance, even under challenging working conditions. Its construction guarantees minimal wear and tear, ensuring a prolonged product lifespan.2. Precise Grinding: The 7-inch wheel has been engineered to deliver precise grinding and smoothing results. Its balanced design ensures smooth operation and reduced vibrations, allowing for consistent and accurate material removal. This feature enables users to achieve desired finishes promptly and efficiently.3. Versatility: The grinding wheel is compatible with various materials, including metal, stone, ceramics, and more. Its versatility enables users to tackle a wide range of applications, making it an indispensable tool in industries such as construction, automotive, and manufacturing.4. Easy Installation: Designed with user convenience in mind, this grinding wheel features a hassle-free installation process. Equipped with a universal spindle size, it can be quickly mounted on most grinders, reducing downtime and improving productivity.5. Enhanced Safety: Prioritizing user safety, the grinding wheel incorporates features such as reinforced construction and adequate heat dissipation. These safety measures minimize the risk of accidents, ensuring a secure working environment.6. Performance Efficiency: The 7-inch size of the wheel allows for greater surface coverage, resulting in improved efficiency and time-saving benefits. The wheel's optimal composition guarantees smooth and consistent grinding, reducing the need for frequent tool changes.Conclusion:The introduction of the high-quality 7-inch grinding wheel has made a significant impact on professionals and hobbyists in various industries. With its durable construction, precise grinding capabilities, and enhanced safety features, this tool is set to elevate the standards of grinding efficiency, while maintaining the company's reputation for producing reliable and innovative products.As the company continues to pave the way in the field of industrial tools and machinery, the 7-inch grinding wheel stands out as a testament to their commitment to delivering superior performance and meeting the evolving needs of their customers.

Read More

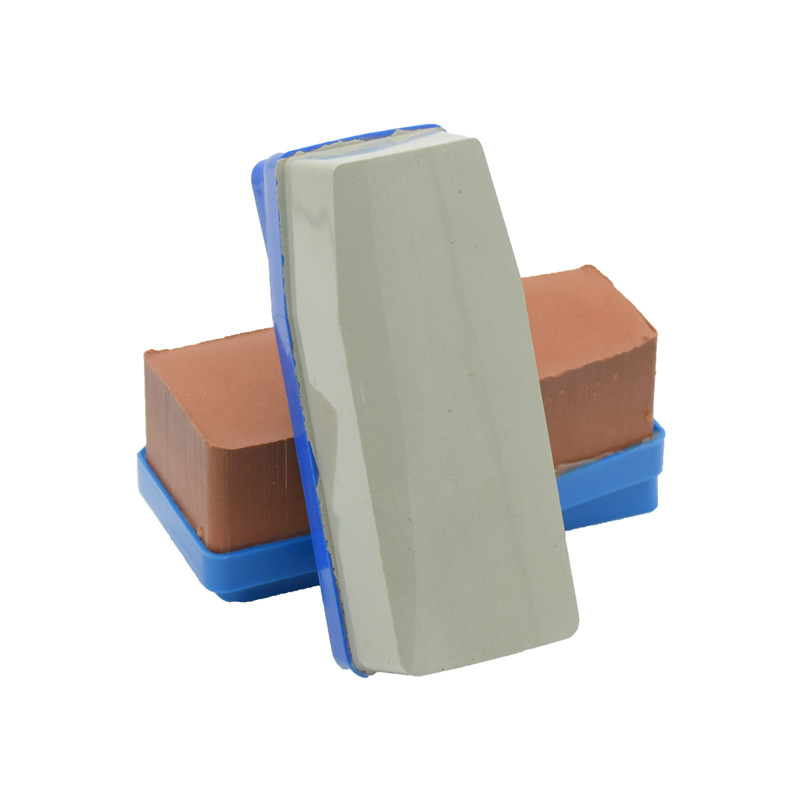

Floor Polishing Pad: Achieve Gleaming Floors with Professional Grade Tools

Floor Polishing Pad: A New Generation of High-Quality Polishing ToolsFloor polishing is an essential task in any commercial or residential building. However, it is often a tedious and time-consuming task that requires the use of specialized tools and high-quality equipment. This is where floor polishing pads come into the picture. The latest innovation in the field of floor polishing, floor polishing pads are designed to make the process faster, easier, and more efficient.Floor Polishing Pad is a leading company that specializes in the production of high-quality floor polishing pads. The company has been in the industry for more than a decade, and over the years, it has established itself as a trusted name in the market. Floor Polishing Pad offers a wide range of polishing pads that are designed to cater to the different needs of its customers.One of the most innovative products from the company is its Diamond Floor Polishing Pads. This product is designed to provide a long-lasting and superior quality finish on various types of floors, including marble, granite, concrete, terrazzo, and more. These pads are made from high-quality materials, and they are designed to deliver consistent performance over a long period.The Diamond Floor Polishing Pads are available in different sizes and grit levels, making them suitable for various polishing tasks. They are easy to use and can be attached to any standard floor buffer or polisher. The pads are also compatible with different polishing compounds, ensuring that customers can achieve the desired finish.Apart from the Diamond Floor Polishing Pads, the company also offers other innovative products. The Resin Floor Polishing Pads, for instance, are designed to provide a high-gloss finish on concrete floors. These pads are made from resin and are suitable for wet and dry polishing. The company also offers a range of Polishing Buffs that are designed to provide a high-quality finish on metal and glass surfaces.The success of Floor Polishing Pad can be attributed to its commitment to quality and customer satisfaction. The company has a team of experienced professionals who are dedicated to ensuring that its customers get the best value for their money. The company also invests heavily in research and development to ensure that its products remain innovative and relevant in the market.Floor Polishing Pad has a robust distribution network that allows it to reach customers in different parts of the world. The company has also established partnerships with other industry players, including equipment manufacturers, to ensure that its products are compatible with the latest polishing tools.In conclusion, Floor Polishing Pad is a leading company that specializes in the production of high-quality floor polishing pads. The company's innovative products, including its Diamond Floor Polishing Pads, Resin Floor Polishing Pads, and Polishing Buffs, have won the trust of its customers. With its commitment to quality and customer satisfaction, Floor Polishing Pad is poised to remain a dominant player in the market.

Read More