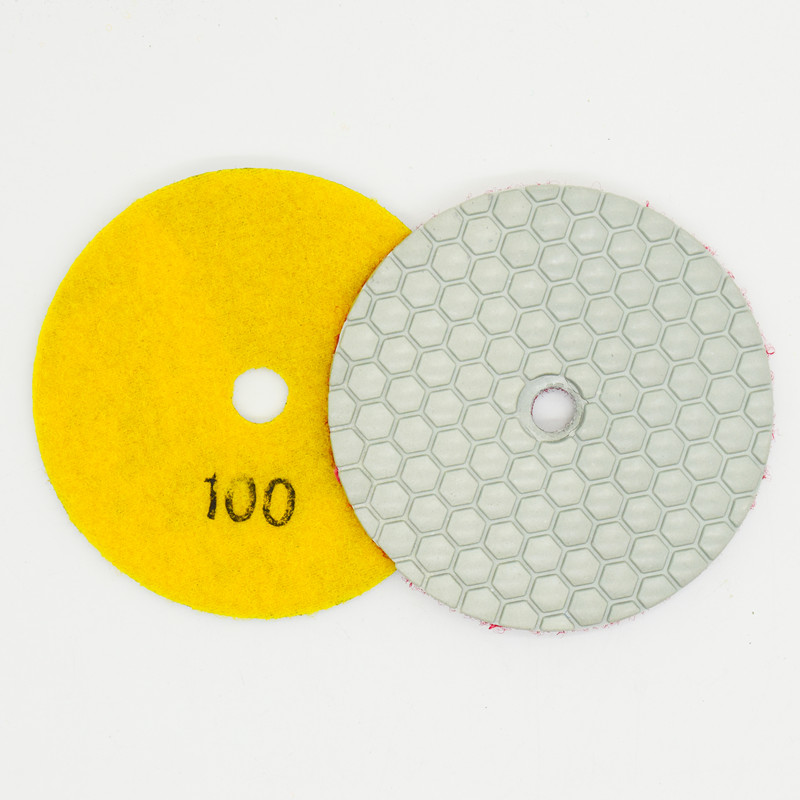

New dry polishing pads revolutionize the industry

By:Admin

The Dry Polishing Pads are manufactured by a leading company in the stone and concrete polishing industry. With over 20 years of experience, the company has become a reputable and trusted name in the market. Their dedication to innovation and quality has led to the development of these groundbreaking dry polishing pads, which are already making waves in the industry.

The dry polishing pads are made with high-quality materials that are designed to provide exceptional performance and durability. They are suitable for use on a wide range of surfaces including granite, marble, and concrete, and are compatible with most standard polishing machines. The pads are available in a variety of grit sizes, allowing for customizable polishing results.

One of the key advantages of the Dry Polishing Pads is their ability to drastically reduce polishing times. Because they do not require water, there is no need to wait for surfaces to dry before proceeding with the next steps of the polishing process. This not only saves time, but it also reduces the overall labor costs associated with traditional wet polishing methods.

Furthermore, the absence of water means that there is significantly less mess and cleanup involved when using these pads. This is not only a convenience for the operator, but it also leads to a safer and more organized work environment. Additionally, the lack of water eliminates the risk of water stains on the polished surfaces, resulting in a cleaner and more professional finish.

The high durability of the Dry Polishing Pads is another standout feature. They are designed to withstand the rigorous demands of the polishing process, providing consistent and high-quality results throughout their lifespan. This longevity makes them a cost-effective option for businesses looking to improve their polishing efficiency and reduce overall expenses.

In addition to their performance benefits, the Dry Polishing Pads also contribute to a more sustainable approach to stone and concrete polishing. By eliminating the need for water, these pads reduce water consumption and the need for water disposal, which is a significant environmental benefit. This aligns with the company's commitment to sustainability and responsible manufacturing practices.

The company takes great pride in its role as a leader in the stone and concrete polishing industry. Their dedication to providing innovative and high-quality products has earned them a strong reputation among professionals in the field. The introduction of the Dry Polishing Pads further solidifies their position as a forward-thinking company that is committed to meeting the evolving needs of the industry.

Moving forward, the company continues to invest in research and development to further enhance their product offerings and drive innovation in the industry. Their goal is to continue to provide cutting-edge solutions that enable businesses to achieve superior results while minimizing their environmental impact.

In conclusion, the introduction of Dry Polishing Pads marks a significant milestone in the stone and concrete polishing industry. With their sustainable, high-performance, and cost-effective benefits, these pads are set to become a game-changer for professionals in the field. As the company continues to lead the way in innovation and quality, the future looks bright for the industry and those who rely on high-quality polishing solutions.

Company News & Blog

Discover the Benefits of a Car Polish Pad Designed for Grinders

Title: New Car Polish Pad Offers Enhanced Performance and Superior Polishing ResultsIntroduction:In a constant pursuit to deliver innovative solutions and meet the evolving demands of car enthusiasts, {Company Name} is proud to announce the launch of their latest product, a Car Polish Pad for Grinders. This cutting-edge tool aims to revolutionize the car polishing experience by offering enhanced performance and delivering superior polishing results. With its state-of-the-art design and advanced technology, the Car Polish Pad is set to become a game-changer in the automotive industry.Body:1. Unveiling the Car Polish Pad:Designed by a team of experts with extensive knowledge and experience in automotive detailing, the Car Polish Pad is a high-quality accessory specifically crafted to provide unparalleled polishing capabilities. The pad's unique composition and construction enable it to handle a variety of surfaces effortlessly, ensuring an impeccable finish every time.2. Exceptional Performance:Equipped with an advanced foam material, the Car Polish Pad offers exceptional polishing performance. The pad's finely engineered cells are designed to retain polish effectively, reducing waste and maximizing efficiency. This innovative technology allows users to achieve professional-grade results in a fraction of the time traditionally required for car polishing.3. Versatility and Durability:The Car Polish Pad has been designed to cater to a wide range of automotive surfaces, making it a versatile tool for car enthusiasts and professionals alike. Engineered to be durable and long-lasting, this pad is built to withstand regular usage without compromising its polishing efficiency. With the Car Polish Pad, users can expect consistent and impressive results, regardless of the surface being polished.4. Easy to Use:Utilizing the Car Polish Pad is a breeze, even for those new to automotive detailing. The pad's ergonomic design ensures a comfortable grip and facilitates effortless maneuverability during the polishing process. Its compatibility with most grinders further simplifies use, ensuring seamless integration into existing tools and routines.5. Safety Features:{Company Name} places utmost importance on customer safety. To this end, the Car Polish Pad is equipped with safety mechanisms that prevent overheating and minimize the risk of damage to the vehicle's surface. This feature provides users with peace of mind, knowing that their vehicle is protected during the polishing process.6. Commitment to Quality:{Company Name}'s dedication to excellence is evident in every aspect of their product development. The Car Polish Pad has undergone rigorous testing to meet the highest standards of quality, providing users with a reliable and efficient tool they can trust. Backed by {Company Name}'s commitment to customer satisfaction, the Car Polish Pad is poised to become a must-have accessory for car enthusiasts and professionals worldwide.Conclusion:With the introduction of their Car Polish Pad for Grinders, {Company Name} reaffirms their status as a leader in the automotive industry. Delivering superior performance, durability, and safety features, this cutting-edge accessory sets a new standard for car polishing tools. The Car Polish Pad's innovative design and unwavering commitment to quality make it an essential addition to any car enthusiast's arsenal. With its launch, {Company Name} continues to enhance the car polishing experience, enabling users to achieve showroom-like finishes and take pride in their well-maintained vehicles.

Unlocking the Mystery of Gold's Metallic Bonds: A Fascinating Study Reveals Intriguing Properties

Title: Advancements in Metallic Bond Technology Unveiled by Industry LeaderIntroduction:In a dynamic and ever-evolving industry, the field of metallic bonding has witnessed significant advancements with the introduction of a groundbreaking technology by a leading company. This groundbreaking innovation, known as Gold Metallic Bonds (GMB), aims to revolutionize various sectors that heavily rely on the inherent properties of metallic bonding. With its unique characteristics and applications, GMB holds the potential to transform industries such as electronics, energy, automotive, and aerospace.I. Understanding Gold Metallic Bonds:Historically, metallic bonds have been crucial in facilitating the formation of metallic solids. They involve the sharing of delocalized electrons among a lattice of positively charged metal ions, resulting in a highly conductive and malleable material. With Gold Metallic Bonds, this classic form of bonding takes a leap forward by incorporating gold as a key component in the bonding process. Gold, renowned for its exceptional conductivity and corrosion resistance, enhances the inherent properties of the metallic bond, opening up new possibilities for technological breakthroughs.II. Enhanced Conductivity for Electronics Industry:In the realm of electronics, Gold Metallic Bonds prove to be invaluable. As the demand for faster and more efficient electronic devices continues to rise, GMB can greatly enhance conductivity, leading to improved performance. By incorporating GMB into circuitry, transmission speeds can be significantly enhanced, minimizing data loss and optimizing overall device functionality. Moreover, this technology offers increased resistance to corrosion, ensuring longevity and reliability in electronic components.III. Addressing Energy Efficiency Challenges:The energy sector is another industry that stands to benefit from Gold Metallic Bonds. With the growing focus on renewable energy sources, GMB can aid in increasing conversion efficiency and reducing energy loss. From solar panels to wind turbines, GMB utilization can enhance energy capture and transfer mechanisms, enabling the generation of cleaner, more sustainable power. Additionally, GMB's corrosion resistance properties contribute to prolonged equipment life, lowering maintenance costs and improving overall efficiency.IV. Reinventing Automotive Engineering:In the automotive industry, safety and performance are paramount. Gold Metallic Bonds can redefine vehicle engineering by improving structural integrity and crashworthiness. The inclusion of GMB in critical components, such as chassis frames and safety structures, significantly enhances the material's strength, leading to more robust and safer vehicles. Furthermore, GMB's conductivity also invites advancements in the electric vehicle domain, allowing for better battery performance and efficient power delivery.V. Aiding Aerospace Applications:The aerospace industry also stands to benefit from Gold Metallic Bonds, particularly in aircraft design and construction. The lightweight and high-strength properties of GMB make it an ideal candidate for applications like airframes and turbine engines. With GMB, aerospace manufacturers can achieve weight reduction without sacrificing structural integrity, leading to improved fuel efficiency and longer range capabilities. Moreover, GMB's resistance to corrosion ensures durability in harsh environments, increasing aircraft lifespan and reducing maintenance costs.Conclusion:The introduction of Gold Metallic Bonds marks a significant milestone in the field of metallic bonding technology. With its unique properties, GMB has the potential to revolutionize a multitude of industries, including electronics, energy, automotive, and aerospace. Through enhanced conductivity, increased corrosion resistance, and improved structural integrity, GMB can pave the way for technological advancements that improve efficiency, safety, and sustainability. As companies continue to explore the vast potential of Gold Metallic Bonds, a new era of innovation and progress beckons, promising transformative changes across various sectors.

A Guide to Aluminum Backer Pads for Polishing and Grinding

Title: Cutting-Edge Aluminum Backer Pad Revolutionizes Polishing Techniques in the Construction IndustryIntroduction:In an ever-evolving construction industry, technological advancements play a crucial role in improving efficiency and effectiveness. One such innovation gaining significant attention is the groundbreaking Aluminum Backer Pad, developed by a renowned industry leader. This state-of-the-art product is set to redefine polishing techniques, offering a host of benefits that will undoubtedly propel the construction industry into a new era of excellence.Product Overview:The Aluminum Backer Pad is a cutting-edge tool designed specifically for polishing and grinding applications in the construction and renovation sectors. Made from high-quality aluminum, this innovative product demonstrates exceptional durability and versatility, making it an essential addition to any construction professional's toolkit.Unmatched Durability:Aluminum, renowned for its strength and resilience, forms the foundation of this revolutionary backer pad. Unlike traditional backer pads made of plastic or rubber, this aluminum variant offers superior longevity, withstanding rigorous use and extended periods of polishing without succumbing to wear and tear. This unparalleled durability ensures a longer lifespan, significantly reducing replacement costs for construction companies and individual contractors alike.Optimal Balance and Stability:The Aluminum Backer Pad's ingenious design incorporates a high level of balance and stability, providing an enhanced polishing experience. Its unique geometric structure enables efficient distribution of pressure across the polishing surface, resulting in a smoother and more even finish. This eliminates the risk of uneven polishing and facilitates the creation of flawlessly polished surfaces, ideal for a variety of applications, including concrete, natural stone, and ceramics.Enhanced Versatility:This aluminum-based backer pad offers exceptional versatility, adapting to various polishing methods and surfaces. With its universal fitting system, construction professionals can seamlessly attach the pad to most commonly used polishing machines, eliminating the need for multiple backer pads for different projects. This adaptability saves time and effort, while ensuring consistent and exceptional results across diverse applications.Efficient Heat Dissipation:Heat generation during polishing processes can lead to equipment failure and reduced efficiency. The Aluminum Backer Pad addresses this challenge by incorporating advanced heat dissipation technology. This innovative design allows for efficient air circulation, preventing the buildup of excess heat. By minimizing heating issues, the backer pad enables longer and uninterrupted periods of polishing, enhancing productivity and reducing project completion times.Eco-Friendly Advantages:In line with growing environmental concerns, the Aluminum Backer Pad supports sustainable practices within the construction industry. Its aluminum composition is fully recyclable, reducing waste and promoting a greener approach to construction projects. By investing in this eco-friendly product, construction companies can bolster their commitment to environmental responsibility, appealing to both clients and regulatory bodies.Conclusion:The introduction of the Aluminum Backer Pad signifies a revolutionary leap in polishing techniques within the construction industry. Its exceptional durability, balance, and versatility offer construction professionals the ability to achieve flawless results consistently. Furthermore, its efficient heat dissipation and eco-friendly composition highlight the commitment to excellence and sustainability that drive the company's development of cutting-edge tools and equipment.As the construction industry continues to evolve, the Aluminum Backer Pad stands poised to become an indispensable asset for countless polishing applications. With its host of benefits, this groundbreaking product promises to streamline operations, expedite project completion, and elevate the overall quality of construction and renovation projects.

Metal Atom Forms Bonds With Nonmetal Element

Metal Atom Bonds With Nonmetal: A Breakthrough in Chemical ResearchIn a groundbreaking development in the field of chemistry, researchers at {} have discovered a new way for metal atoms to bond with nonmetal atoms, potentially opening up a wide range of possibilities for the creation of new materials and compounds. This breakthrough has the potential to revolutionize various industries, including pharmaceuticals, electronics, and materials science.{} is a renowned research institution that has been at the forefront of scientific innovation for decades. With state-of-the-art facilities and a team of world-class researchers, the institution has made significant contributions to various scientific fields.The recent discovery revolves around the bonding of metal atoms with nonmetal atoms, a process that was previously thought to be extremely challenging to achieve. By utilizing advanced computational modeling and experimental techniques, the researchers at {} were able to demonstrate a novel approach to creating these chemical bonds, which has the potential to greatly expand the toolbox of chemists and materials scientists.Traditionally, chemical bonds between metals and nonmetals are known to be highly polarized, with the metal atom donating electrons to the nonmetal atom. This results in the formation of ionic compounds, which often exhibit distinct properties such as high melting points and electrical conductivity. However, the new approach discovered by the researchers at {} allows for the formation of covalent bonds between metal and nonmetal atoms, representing a significant departure from conventional wisdom in the field of chemistry.The implications of this discovery are vast. Covalent bonds between metal and nonmetal atoms have the potential to give rise to new classes of materials with unique properties and applications. For example, the development of novel semiconductor materials with enhanced electronic properties could revolutionize the field of electronics, leading to the creation of more efficient and powerful electronic devices.Furthermore, this breakthrough has the potential to impact the field of catalysis, as the ability to form covalent bonds between metal and nonmetal atoms opens up new possibilities for the design of catalysts with unprecedented reactivity and selectivity. This could have far-reaching implications for a wide range of industrial processes, from the production of fuels and chemicals to environmental remediation.The potential applications of this discovery also extend to the field of pharmaceuticals. The ability to form covalent bonds between metal and nonmetal atoms could lead to the development of new classes of drug molecules with enhanced potency and selectivity, potentially leading to breakthroughs in the treatment of various diseases.The researchers at {} are currently exploring the practical applications of this discovery, working closely with industry partners to translate their findings into real-world technologies. Through collaborations with companies in the electronics, materials, and pharmaceutical industries, the institution aims to harness the potential of covalent metal-nonmetal bonds to develop innovative solutions that address pressing societal and technological challenges.As the research team at {} continues to delve deeper into the potential applications of their discovery, the scientific community eagerly anticipates the unveiling of new breakthroughs and innovations that could reshape various industries. This latest development represents a testament to the institution's commitment to pushing the boundaries of scientific knowledge and driving meaningful advancements that have the potential to make a lasting impact on the world.

The Latest Advances in Hardware Machines You Need to Know About

[HARDWARE MACHINE] Unveils Latest Innovation in Industrial Equipment[HARDWARE MACHINE], a leading manufacturer in the industrial equipment sector, has recently unveiled its latest innovation in machinery. With a strong focus on technological advancements and cutting-edge designs, the company is set to revolutionize the industry with its new product offering.The newly released machinery is designed to cater to the needs of various sectors within the industrial landscape, including manufacturing, construction, and logistics. This versatile approach has positioned [HARDWARE MACHINE] as a frontrunner in providing innovative solutions that are tailored to meet the evolving demands of the market."We are thrilled to introduce our latest innovation in industrial equipment. This new machinery sets a benchmark for performance, reliability, and efficiency, and underscores our commitment to delivering top-quality products to our customers," said the spokesperson for [HARDWARE MACHINE].The new machinery boasts a range of features that set it apart from conventional equipment, including advanced automation capabilities, enhanced precision, and intuitive user interfaces. These features are aimed at streamlining operations, improving productivity, and minimizing downtime, thereby offering significant cost savings for businesses.Furthermore, [HARDWARE MACHINE] has integrated state-of-the-art safety features into its latest innovation, ensuring a secure and hazard-free operating environment for workers. This emphasis on safety aligns with the company's dedication to promoting a sustainable and responsible approach to industrial equipment.In addition to its technological advancements, the new machinery from [HARDWARE MACHINE] also embodies a commitment to environmental sustainability. By incorporating energy-efficient components and reducing emissions, the company is contributing to the global movement towards eco-friendly practices in the industrial sector.One of the key highlights of the new machinery is its adaptability to diverse applications, catering to a wide range of industrial processes. Whether it is precision engineering in manufacturing or heavy-duty operations in construction, the versatility of [HARDWARE MACHINE]'s latest innovation makes it a valuable asset for businesses across various sectors.The launch of this groundbreaking machinery reinforces [HARDWARE MACHINE]'s position as an industry leader, known for its relentless pursuit of excellence and innovation. The company's distinguished track record of delivering high-performance equipment has earned it the trust and confidence of customers worldwide.The unveiling of the latest innovation comes at a time when the industrial sector is undergoing rapid transformation, driven by technological advancements and evolving market dynamics. As businesses strive to stay ahead of the curve and meet the demands of a competitive landscape, [HARDWARE MACHINE] aims to provide them with the cutting-edge tools they need to thrive and succeed.With a strong emphasis on research and development, [HARDWARE MACHINE] continues to push the boundaries of what is possible in the realm of industrial equipment. The company's unwavering commitment to innovation and customer satisfaction has cemented its reputation as a trailblazer in the industry.Looking ahead, [HARDWARE MACHINE] remains dedicated to pushing the boundaries of technological innovation, with a focus on delivering products that redefine industry standards. As the company continues to set new benchmarks for excellence, its latest innovation serves as a testament to its vision of shaping the future of industrial equipment.In summary, the unveiling of [HARDWARE MACHINE]'s latest innovation represents a significant milestone in the realm of industrial equipment. With its advanced features, focus on safety and sustainability, and versatility across applications, the new machinery is poised to make a lasting impact on the industry. As [HARDWARE MACHINE] continues to lead the way in innovation, businesses can look forward to a future where cutting-edge machinery transforms their operations and drives success.

Get the Best Resin Bond for Improved Industrial Applications

[Company Name] Develops Innovative Resin Bond for Improved Performance in Industrial Applications[City Name], [Date] – [Company Name], a leading manufacturer of industrial products and solutions, has recently introduced its latest resin bond innovation – the T-140 Resin Bond. This revolutionary product is set to significantly enhance performance and efficiency in a wide range of industrial applications. Combining cutting-edge technology with the company's extensive expertise, it promises to redefine industry standards.Resin bonds are an essential component in various industrial processes such as grinding, cutting, and polishing, providing a strong adhesive between abrasive particles and the tool. The quality of the resin bond directly impacts the overall performance of the tool, therefore influencing the productivity and output of the process. Recognizing the significance of resin bonds, [Company Name] invested significant resources towards developing the T-140 Resin Bond.The T-140 Resin Bond is designed to offer exceptional strength and durability, ensuring longer tool life and reduced downtime. Its unique composition and manufacturing process make it more resistant to heat, friction, and wear compared to conventional resin bonds currently available in the market. This characteristic is particularly critical in high-intensity industrial applications where tools are subject to extreme conditions.One of the key advantages of the T-140 Resin Bond is its ability to maintain a consistently sharp cutting edge throughout the operation. This attribute leads to improved precision and accuracy, optimizing the overall productivity of the process. By minimizing the need for tool replacement or re-sharpening, this resin bond ensures uninterrupted workflow, reducing costs and time wastage for manufacturers.Moreover, the T-140 Resin Bond has demonstrated exceptional performance in a variety of materials, including metal, stone, and composites. Its versatility makes it a suitable choice for a broad range of industries such as automotive, aerospace, construction, and manufacturing. Regardless of the application, users can expect consistent and excellent results with the T-140 Resin Bond.Safety is another critical factor that [Company Name] prioritizes in its product development process. The T-140 Resin Bond adheres to strict safety standards, ensuring a reliable and secure operation for users. By minimizing the risk of tool slippage or failure, this resin bond significantly enhances the overall safety of industrial processes, protecting workers and minimizing accidents."The development of the T-140 Resin Bond is a testament to our commitment to innovation and continuous improvement," said [Company Name]'s CEO. "Our dedicated team of engineers and technicians have worked tirelessly to develop a resin bond that surpasses industry standards in terms of performance, durability, and safety. This breakthrough will undoubtedly benefit our customers and the industries they serve."To ensure the widespread availability of the T-140 Resin Bond, [Company Name] has increased its manufacturing capacity and streamlined its distribution channels. The product is now readily accessible through the company's extensive network of authorized distributors, ensuring prompt delivery and excellent customer support.As [Company Name] introduces the T-140 Resin Bond to the market, it reinforces its position as a leading provider of innovative industrial solutions. By combining cutting-edge technology, extensive expertise, and customer-centricity, the company continues to drive progress and shape the future of various industries.About [Company Name]:[Company Name] is a renowned manufacturer of industrial products and solutions trusted by customers worldwide. With a commitment to excellence, innovation, and customer satisfaction, the company provides reliable and high-quality solutions tailored to meet the specific needs of different industries. Through continuous research and development, [Company Name] ensures it stays at the forefront of technological advancements, delivering products that surpass industry standards.###Press Contact:[Contact Name][Title][Company Name][Email Address][Phone Number]

High-Quality 100mm Grinding Wheel for Precision Grinding

{Company Name} introduces new 100mm Grinding Wheel, further expanding their line of high-quality abrasives.{Company Name}, a leading manufacturer of industrial abrasives, is proud to announce the addition of the new 100mm Grinding Wheel to their product line. This new product is designed to meet the growing demand for high-performance grinding tools in various industries.The 100mm Grinding Wheel is specifically engineered for precision grinding, with a focus on durability and efficiency. It is suitable for use on a wide range of materials, including metals, stainless steel, and non-ferrous metals. The wheel is designed for use with angle grinders and features a 100mm diameter, making it ideal for both professional and DIY applications."We are excited to introduce the new 100mm Grinding Wheel to our customers," said a spokesperson for {Company Name}. "We understand the importance of having reliable and efficient grinding tools, and we believe that this new product will meet the needs of our customers across different industries."{Company Name} is known for their commitment to producing high-quality abrasives that deliver consistent performance and durability. The 100mm Grinding Wheel is no exception, as it is manufactured using advanced technology and high-quality materials. The wheel is also designed to minimize vibration and noise during operation, providing a smooth and comfortable grinding experience for the user.In addition to its superior performance, the 100mm Grinding Wheel also boasts a longer service life, which can help reduce downtime and maintenance costs for users. This makes it a cost-effective solution for businesses and individuals looking for a reliable grinding tool that can withstand demanding applications.The introduction of the 100mm Grinding Wheel reflects {Company Name}'s ongoing commitment to innovation and product development. By continuously expanding their product line, the company aims to meet the evolving needs of their customers and remain at the forefront of the abrasives industry."Our team of engineers and technicians have worked tirelessly to develop the 100mm Grinding Wheel, and we are confident that it will exceed the expectations of our customers," added the spokesperson. "We are dedicated to providing solutions that help our customers improve their productivity and efficiency, and this new product is a testament to that commitment."Customers can expect the same level of customer support and technical expertise that {Company Name} is known for when purchasing the 100mm Grinding Wheel. The company's knowledgeable sales team is available to provide guidance and assistance in selecting the right abrasive products for specific applications, ensuring that customers can make informed decisions that will ultimately benefit their operations.As the demand for high-performance grinding tools continues to grow, {Company Name} remains focused on delivering innovative solutions that set new standards for quality and performance. The introduction of the new 100mm Grinding Wheel is a testament to the company's dedication to meeting the needs of their customers and maintaining their position as a leader in the abrasives industry.

High-Quality 125mm Car Polishing Pads for Ultimate Shine

Car enthusiasts and detailers will be thrilled to hear about the latest addition to the {Company Name} product lineup – the 125mm Car Polishing Pads. These high-quality pads have been specifically designed to provide a professional finish to any car, ensuring a flawless and glossy appearance.The 125mm Car Polishing Pads are made from premium materials, including a carefully selected foam and microfiber blend. This combination allows for maximum effectiveness in removing swirl marks, scratches, and other imperfections from the surface of the vehicle. The pads are also suitable for use with a variety of polishing compounds and can be easily attached to most rotary and dual-action polishers.With a focus on both performance and durability, the {Company Name} 125mm Car Polishing Pads are built to withstand the rigors of regular use. The carefully engineered design ensures that the pads maintain their shape and density, even when subjected to high speeds and pressure. This means that users can rely on the pads to consistently deliver a superior polishing experience without the risk of deterioration or disintegration.In addition to their outstanding performance, the 125mm Car Polishing Pads also offer practical benefits for users. The hook and loop backing ensures quick and easy pad changes, allowing for a seamless transition between different stages of the polishing process. The pads are also machine washable, making them easy to clean and maintain for prolonged use.{Company Name} is renowned for its dedication to providing innovative and high-quality automotive detailing products. The addition of the 125mm Car Polishing Pads to their product range further solidifies their position as a leading supplier in the industry. With a commitment to meeting the needs of professionals and enthusiasts alike, {Company Name} continues to push the boundaries of excellence in car care and maintenance.The comprehensive line of {Company Name} products includes a wide range of polishing compounds, microfiber towels, detailing brushes, and more. These products have gained a loyal following among users who demand nothing less than the best for their vehicles. With the introduction of the 125mm Car Polishing Pads, {Company Name} further demonstrates its unwavering dedication to delivering superior solutions for car detailing and maintenance.The 125mm Car Polishing Pads are set to become an essential addition to the toolkit of every detailer and automotive enthusiast. Their exceptional performance, durability, and user-friendly design make them the perfect choice for achieving professional-grade results when polishing and restoring vehicles. Whether used in professional detailing shops or for personal car care, these pads are sure to impress with their exceptional performance and reliability.{Company Name} remains committed to driving innovation and quality in the automotive detailing industry, and the 125mm Car Polishing Pads are a testament to this ongoing dedication. As car enthusiasts continue to demand the best for their vehicles, {Company Name} stands ready to meet and exceed their expectations with exceptional products like the 125mm Car Polishing Pads.

The Difference Between Metal Bonds and Nonmetals Explained

Metal Bonds and Nonmetal, a leading global company in the field of industrial materials, recently announced a breakthrough in the development of a new type of metal bond and nonmetal technology. The company has been a pioneer in the industry for over two decades and has continuously strived to push the boundaries of innovation and advancement in industrial materials.With a strong focus on research and development, Metal Bonds and Nonmetal has been able to stay at the forefront of the industry. The company's team of experts has been working tirelessly to develop new and advanced materials that can meet the evolving needs of various industries. This dedication to innovation has now resulted in the development of a groundbreaking metal bond and nonmetal technology that is set to revolutionize the market.The new technology developed by Metal Bonds and Nonmetal offers a unique combination of metal bonds and nonmetal materials, creating a highly versatile and durable material that can be used across a wide range of applications. This innovative approach to material development has the potential to significantly impact industries such as automotive, aerospace, construction, and more.The new metal bond and nonmetal technology has been proven to exhibit superior strength, durability, and resistance to wear and tear. This makes it an ideal choice for applications that require high-performance materials, such as cutting tools, grinding wheels, and industrial machinery. The technology's versatility also makes it suitable for a wide range of other applications, providing a cost-effective and sustainable solution for various industries.Metal Bonds and Nonmetal's new technology is expected to disrupt the market by offering a unique alternative to conventional materials. With its superior performance and adaptability, the new metal bond and nonmetal technology has the potential to replace traditional materials in many applications, offering significant cost savings and environmental benefits.The company's commitment to sustainability and environmental responsibility is evident in the development of this new technology. By creating a material that is highly durable and long-lasting, Metal Bonds and Nonmetal is contributing to the reduction of waste and the promotion of a more sustainable industrial landscape.Furthermore, the new technology also has the potential to significantly improve the efficiency and productivity of various industries. Its exceptional durability and resistance to wear and tear make it an ideal choice for high-stress applications, allowing for longer tool life and reduced downtime for machinery and equipment.Metal Bonds and Nonmetal has already begun working with industry partners to bring this revolutionary technology to market. The company is confident that the new material will gain rapid acceptance and adoption across various sectors, positioning it as a leader in the advancement of industrial materials.Overall, Metal Bonds and Nonmetal's new metal bond and nonmetal technology represents a significant milestone in the company's journey of innovation and advancement. With its unique combination of strength, durability, and versatility, the new technology has the potential to transform the industrial materials market and bring about positive change for industries around the world. As a company that has consistently demonstrated its dedication to pushing the boundaries of innovation, Metal Bonds and Nonmetal is set to continue leading the way in the development of high-performance and sustainable materials for industrial applications.

Professional Diamond Polishing Pads for Superior Results

[Company Introduction]{Company Name} is a leading provider of high-quality diamond tools for the construction and stone industry. With over 20 years of experience, we have established a strong reputation for delivering top-notch products that meet the demanding needs of our customers. Our dedication to innovation and excellence has made us a trusted partner for professionals in the field, and we are committed to continually pushing the boundaries of what is possible in diamond tool technology.[News Content]In a recent announcement, {Company Name} unveiled its latest breakthrough in diamond tool technology with the release of the 7 Diamond Polishing Pads. These new pads are designed to provide an unmatched level of performance and precision, making them an essential tool for any professional in the stone and construction industry.The 7 Diamond Polishing Pads are the result of years of research and development, incorporating the latest advancements in diamond tool technology. With a focus on durability and effectiveness, these pads are capable of delivering a superior polishing experience that is unmatched in the industry.One of the key features of the 7 Diamond Polishing Pads is the innovative design that allows for maximum contact with the surface being polished. This ensures a more even and consistent finish, resulting in a higher quality end product. Additionally, the pads are engineered to be highly effective on a wide range of materials, from granite and marble to concrete and engineered stone, making them a versatile and valuable tool for professionals in the field.Another notable aspect of the 7 Diamond Polishing Pads is their long-lasting performance. The high-quality diamonds used in the pads are carefully selected and precisely engineered to maintain their sharpness and effectiveness over the long term. This means that professionals can rely on the pads to deliver consistent results, project after project, without the need for frequent replacement or maintenance.{Company Name} has also taken great care to ensure that the 7 Diamond Polishing Pads are easy to use and compatible with a wide range of equipment. Whether used with a hand polisher or a high-speed grinder, these pads are designed to seamlessly integrate into any workflow, allowing professionals to achieve outstanding results with maximum efficiency.Furthermore, the 7 Diamond Polishing Pads are part of {Company Name}'s commitment to sustainability and environmental responsibility. By using the highest quality materials and production processes, the company has minimized the environmental impact of the pads while ensuring maximum performance and longevity.Overall, the release of the 7 Diamond Polishing Pads represents a significant advancement in diamond tool technology, providing professionals in the stone and construction industry with an essential tool for achieving superior results. With their unmatched performance, durability, and versatility, these pads are poised to set a new standard for diamond polishing in the industry. As {Company Name} continues to push the boundaries of what is possible in diamond tool technology, professionals can look forward to even more innovative and high-quality products in the future.